What are the components of precast buildings connected by? Come to the site to see the construction technology!

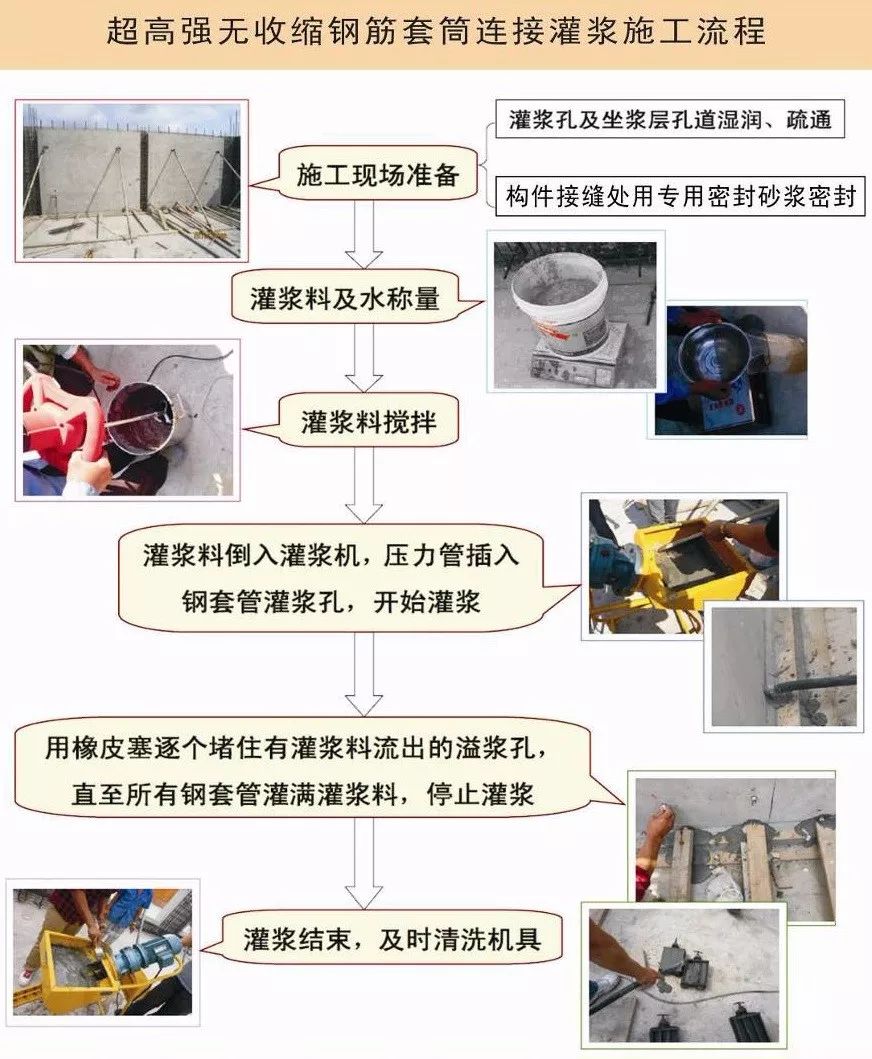

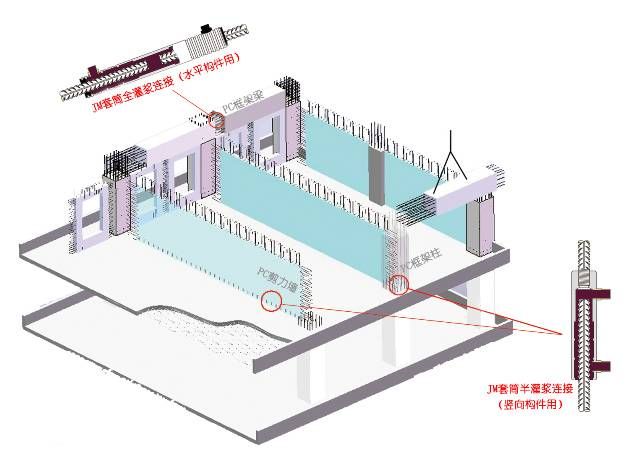

Illustrate the key process of precast building construction sleeve grouting ↓↓↓ as the key process of precast building construction, sleeve grouting is used for the connection of vertical components (such as shear walls and frame columns) and horizontal components (such as frame beams): the purpose of sleeve grouting is to insert ribbed reinforcement into the reinforcement sleeve with grooves in the inner cavity, and then pour special high-strength, non shrinkage grouting material, To achieve the connection effect higher than the strength of the reinforcement base metal: ▲ semi grouting joint schematic ▲ full grouting joint schematic preparation before construction [material preparation] sleeve inspection points: strength, deformation, spheroidization rate, hardness and other grouting material inspection points: strength, deformation, fluidity, durability and other type inspection points: tensile strength and deformation, jgj107 first-class joint standard [machine preparation] [pre work preparation points] 1 Inspection records (number, diameter and reserved length of joint reinforcement) 2 Base course cleaning (grout surface, sleeve interior, joint reinforcement) 3 Plugging (segmented or controlled quantity, curing) 4 Interface watering and wetting 5 Example of construction process of remedial plan [key points for construction] 1 Grouting construction (no mixing, mix proportion, watering and wetting, and speed control) 2 Curing 3 Example of sleeve grouting connection of three components of ambient temperature 1-precast concrete shear wall connection 2-precast concrete frame column connection 3-precast concrete frame beam connection construction engineering Luban Award appreciation construction engineering Luban exchange daily selection, evening release, learning in fun, common progress ↓ long press identification, join the alliance ↓..