Why is the “1 + 3” standardized design and production system of precast buildings so important?

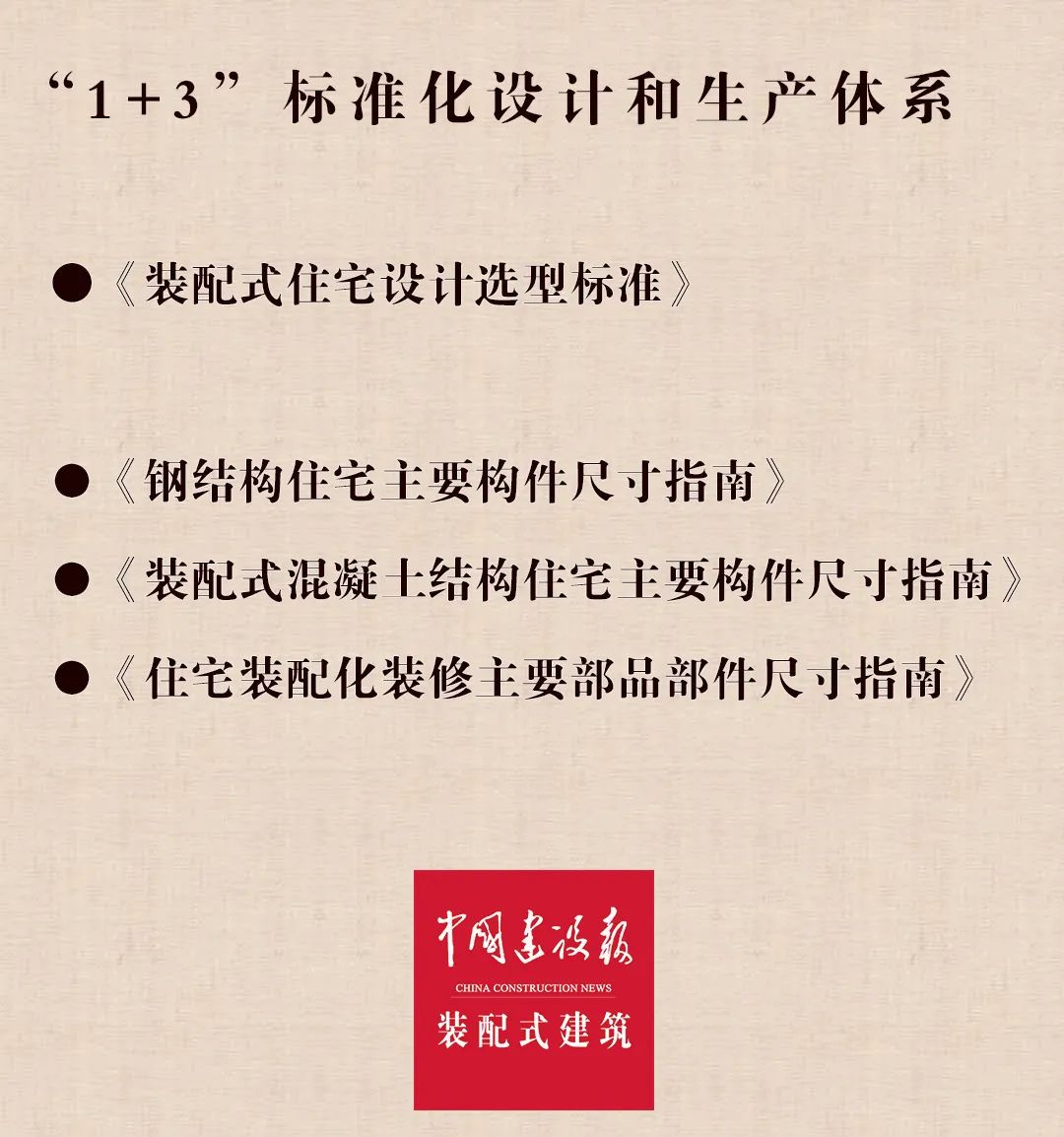

In order to solve this problem, the standard and quota Department of the Ministry of housing and urban rural development proposed to strive to build a “1 + 3” standardized design and production system in 2020, that is, to start the preparation of one standard for the design and selection of precast houses and three guidelines for the dimensions of main components and parts (guidelines for the dimensions of main components of steel structure houses, guidelines for the dimensions of main components of precast concrete structure houses and guidelines for the dimensions of main components of precast decoration of houses).

In August 2020, the guide to the dimensions of main components of steel structure housing was first issued.

Chief Planner: Cha Yanping editor: Gao Yangyang..

What is the “1 + 3” standardized design and production system mentioned in the 14th five year plan for building energy conservation and green building development? What is the significance of promoting the development of precast buildings? It is important to find out this problem.

At present, the standardized design of precast buildings is advancing slowly and does not play the overall role of integrated design.

On April 1, 2022, the industry standard “standard for design and selection of precast houses” was officially implemented, and the last “Puzzle” of the “1 + 3” system was completed.

In September 2021, the guide to the dimensions of the main components of precast concrete structure houses and the guide to the dimensions of the main components of precast decoration of houses were released at the same time, marking the establishment of a standardized production system for dressed buildings.

At present, the relevant standards and guidelines related to the “1 + 3” standardized design and production system have been published and published on the website of the Ministry of housing and urban rural development.

Most projects are still designed according to the traditional mode, and then carry out secondary splitting and deepening design, resulting in complex components, random sizes, various types and low construction and installation efficiency.

The above problems hinder the advantages of precast buildings in efficiency and benefit to a certain extent, making its average cost higher than the traditional construction methods.

The purpose of building a “1 + 3” standardized design and production system is to promote the coordination and unification of the common dimensions of components and parts among design units, construction units and production enterprises, lead the design units to implement the positive design method of “less specifications and more combinations”, and guide the production units to expand the production and use scale of standardized components and parts, so as to gradually reduce the production cost and promote the market-oriented and large-scale development of precast buildings.

At the same time, the common dimensions of precast components and parts are not solidified, and the customized production mode leads to high component cost and low utilization rate of production line.