Wire wound prestressed construction technology of cast pool

steel wire joint.

II.

When the stress fluctuation changes little, it shall be measured once per circle.

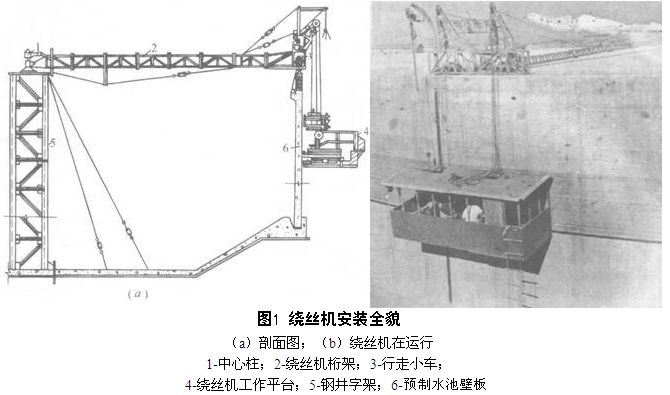

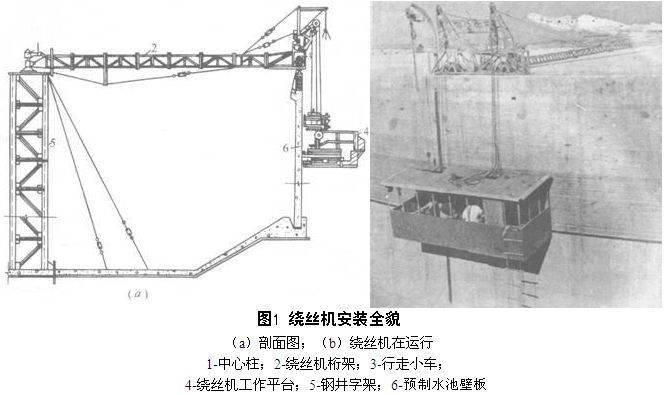

1、 Wire winding device the wire winding machine device is composed of five parts: central well frame, wire winding truss, traveling trolley, wire winding machine and working platform, as shown in Figure 1.

IV.

Select the position next to a channel steel and use the fixture to measure the stress at the same time.

4.

Construction requirements for winding the annular prestressed steel wire.

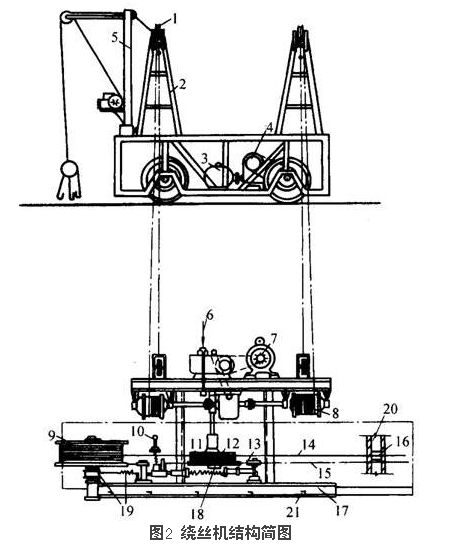

The structure of the wire winding machine is shown in Figure 2.

The stress can be measured by stress meter or electronic strain gauge.

After the wire winding starts, due to the continuous adjustment of the initial tension of the retractor, the stress must be tested 4 ~ 8 times per circle.

3) The parts at both ends of the pool wall where the wire winder cannot be used (the top and bottom of the pool wall) shall be tensioned by electric heating or locally densified.

3.

2.

The stress measurement shall be in a vertical line from top to bottom for stress analysis.

The steel wire joint shall adopt the front joint method, as shown in Figure 3.

After the connection, continue to drive, make the joint slowly pass through the retractor and wrap it on the stress disc.

1 – pulley; 2 – hanger; 3 – traveling trolley motor; 4 – traveling trolley gearbox; 5 – lifting steel wire reel and pull rod; 6 – lifting control system; 7 – winding machine motor; 8 – lifting drum; 9 – steel wire disc; 10 – retractor; 11 – stress disc; 12 – large sprocket; 13 – small sprocket; 14 – this steel wire; 15 – large chain; 16 – steel wire fixture; 17 – wire winder chassis; 18 – large spring; 19 – holding brake system; 20 – embedded channel steel of tank wall plate; 21 – angle steel of working frame chassis ; III.

The first circle shall be wound downward from the top of the pool wall, and the distance from the pool top shall be ≤ 50cm.

Prestressed wire winding 1.

At the same time, adjust the steel wire joint on the stress disc to prevent it from being stacked and extruded until the steel wire joint comes out of the stress disc, and then continue to drive.

Mark the position and sub serial number of the prestressed steel wire or reinforcement on the pool wall.

site pictures..

Clean the concrete floating gravel and dirt on the surface of the outer wall of the pool, and trowel and polish the cement mortar at the outer joint of the wall plate.

That is, when a steel wire is about 3M left in front of the retractor, stop, remove the empty disc, replace the heavy disc, connect the joint in front of the retractor, and rotate the rear steel wire disc in the opposite direction to make the steel wire still tight.

4) protective railings shall be set around the wire winding prestress, and the wound steel wire shall not be impacted by sharp hard or heavy objects.

1) the steel wire joint shall be tightly bound, and the overlapping length shall be ≥ 25cm2).