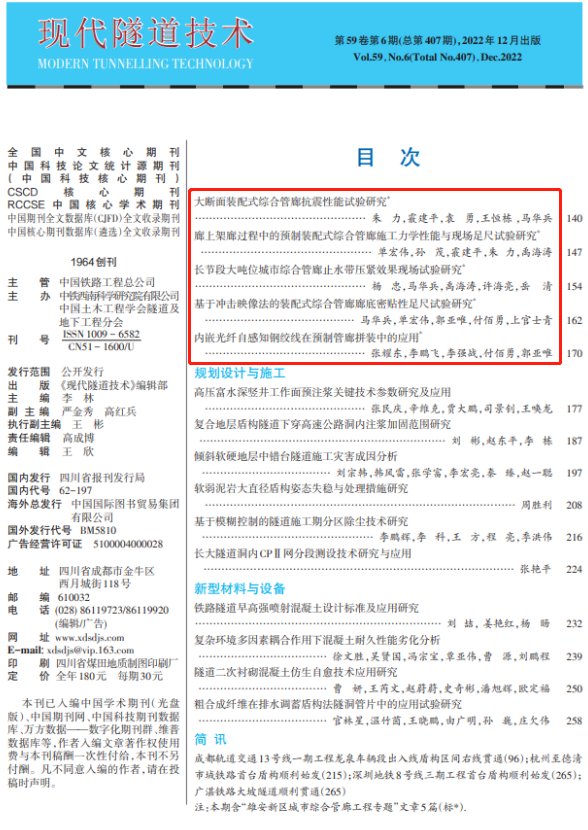

Modern Tunnel Technology publishes the research results of the demonstration project of precast pipe gallery in Xiong’an New Area

On November 19, the test results were reviewed by an expert group established by two academicians.

The pipeline corridor project has applied for 102 patents in total, including 30 invention patents and 72 utility model patents.

Contributed | Edited by Ma Huabing | Reviewed by Yu Yong | Fan Wei..

At the same time, it has also accumulated rich scientific and technological achievements for the company in the construction field of long section and large tonnage cast comprehensive pipe gallery.

The precast pipe gallery is divided into 4m and 8m sections, with 4m sections weighing 201t and 8m sections weighing 402t.

During the implementation of the project, the validation of various processes has been recognized by the expert group and the New Area.

and the Tunnel and Underground Engineering Branch of China Civil Engineering Society.

Founded in 1964, Modern Tunnel Technology is a scientific and technological journal jointly sponsored by China Railway Southwest Academy of Science Co., Ltd.

30 papers have been submitted and 19 papers have been employed.

It is a core journal in the transportation and underground space industry and has high influence.

The project will start construction on March 15, 2021.

Up to now, more than 70 patents have been authorized.

Xiong’an New Area Assembled Pipe Rack Demonstration Project is a key innovative pilot project led by Xiong’an Group and CCCC Group and contracted by CCCC Second Highway Engineering Co., Ltd., integrating scientific research and demonstration.

Recently, five papers, including “Experimental Study on Seismic Performance of Large Section Fabricated Integrated Pipe Rack”, were successfully published in the sixth issue of the Chinese core scientific and technological journal Modern Tunnel Technology in 2022, relying on the demonstration project of Xiong’an New Area’s long section large tonnage integrated precast integrated pipe rack.

The total length of the pipeline corridor demonstration project is 816m.

The technical achievements of the project are currently in the process of sorting out, and the successful publication of this paper has also laid a good foundation for the identification of the follow-up achievements of the project and the reporting of achievements.

Relying on the “construction process of long section and large tonnage assembly type integrated pipe gallery upper rack”, “construction process of TTB250t tire type lifting machine installation pipe gallery” and “long section and large tonnage assembly type integrated pipe gallery full-automatic hydraulic formwork system” summarized by the assembly type pipe gallery project, they won one gold medal, one silver medal and one bronze medal respectively in the third national highway micro innovation competition.

During the implementation process, relying on the three major parts of pipe gallery segment prefabrication, transportation and installation, the project has conducted experimental research and verification on more than ten technical issues, including overall lifting of reinforcement cage, high-precision pipe gallery prefabrication, gallery bottom tightness, segment and joint waterproofing, gallery installation process, cross pit gantry crane installation process, automatic intelligent monitoring, etc, The prefabrication and installation project was successfully completed on August 20.