Quantitative evaluation of adhesion between cement emulsified asphalt slurry and RAP

Keywords Road Engineering | Recycled Asphalt Pavement Materials (RAP) | Cement Emulsified Asphalt Mortar | Interface Adhesion | Quantitative Evaluation Figure 0 Introduction: The high proportion application of recycled asphalt pavement materials (RAP) is one of the hot research topics in the field of highway engineering today.

At home and abroad, qualitative evaluation is often used to evaluate the adhesion degree between cement emulsified asphalt slurry and RAP, and there is a lack of testing methods that are easy to operate and can accurately quantify.

The cold recycling technology of emulsified asphalt is one of them.

The resistance to hydrochloric acid corrosion and adhesion uniformity of the RAP surface slurry layer were characterized by the release of Ca2+and Mg2+within 20 minutes.

A simulation experiment was conducted using HCl solution to erode the thin layer of cement emulsified asphalt slurry.

When the cold recycled mixture is corroded by acidic water, water molecules and H+easily enter the adhesive layer between the adhesive and RAP from the pores, causing the adhesive to easily peel off from the surface of RAP, affecting the water stability and other road performance of the mixture [2-4]

.

However, during the mixing and forming process of cold recycling mixtures, due to the evaporation of water in emulsified asphalt and the interaction with active fillers such as cement, the cement emulsified asphalt slurry on the RAP surface leaves many pores after solidification, which significantly affects the mixing uniformity of the mixture and directly affects the impermeability and coating ability of the cement emulsified asphalt slurry layer on the RAP surface.

It not only saves construction costs, but also benefits environmental protection [1].

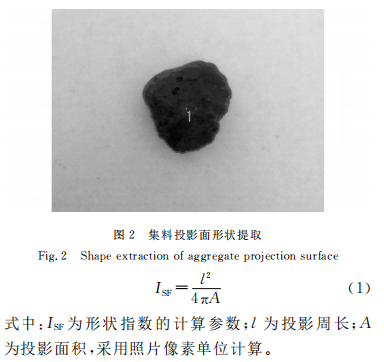

The research results indicate that HCl has corrosive properties on cement emulsified asphalt slurry and can corrode the hydration product phase of cement in the slurry; The shape index of aggregates has little effect on the average film thickness of cement emulsified asphalt slurry; The larger the RAP shape index, the greater the ratio of ion release to adhesion, the lower the resistance of the adhesive layer to hydrochloric acid corrosion, and the worse the uniformity and grade of adhesion; As the mass ratio of cement to emulsified asphalt C/EA increases, the release of ions first decreases and then increases, and the adhesion of the adhesive first increases and then decreases; When the C/EA is 30%, the ion release is the smallest and the adhesion is the best.

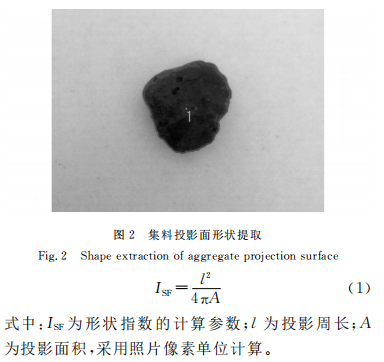

Digital image technology was used to extract two-dimensional shape features of recycled asphalt pavement materials (RAP), and a RAP surface area calculation model was proposed; At the same time, adhesion tests between RAP and cement emulsified asphalt slurry with different shape indices were designed, and corrosion tests were conducted on the adhesive interface of the slurry using HCl solution.

Abstract: There are problems in the cold recycled emulsified asphalt mixture, such as uneven adhesion of cement emulsified asphalt slurry to recycled asphalt pavement material (RAP) and easy peeling after immersion, which directly affect the water stability and road performance of the mixture.