Seven common structural systems and future development direction of precast buildings

Informatization: With the deep integration of informatization and industrialization, information technology will become an important tool and means for the construction industry in the future.

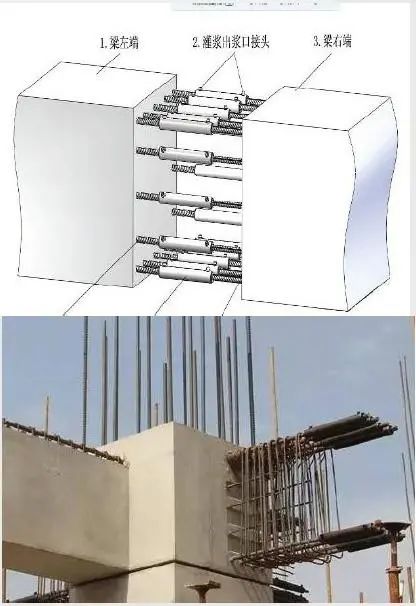

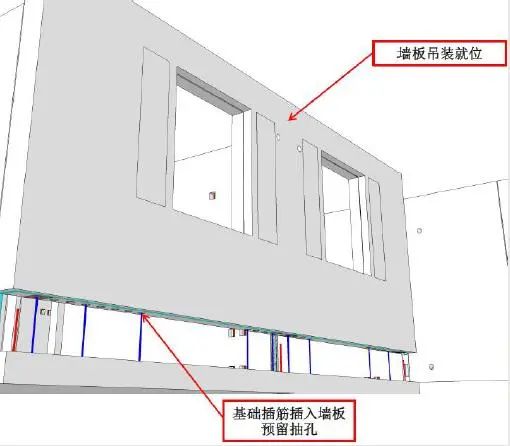

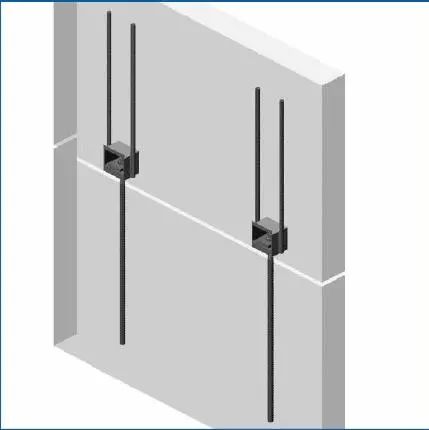

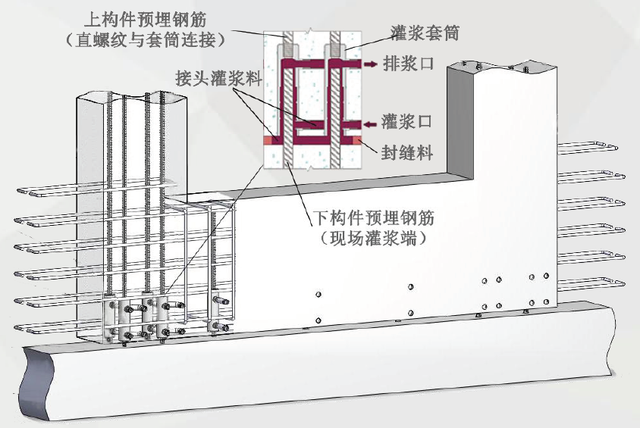

The grouting sleeve connection of reinforced concrete slab structure system is applicable to large-diameter reinforcement, suitable for centralized connection of reinforcement, and can be directly or indirectly connected.

Average cost of a single sleeve (sleeve+grouting material+auxiliary material+labor)=100 yuan.

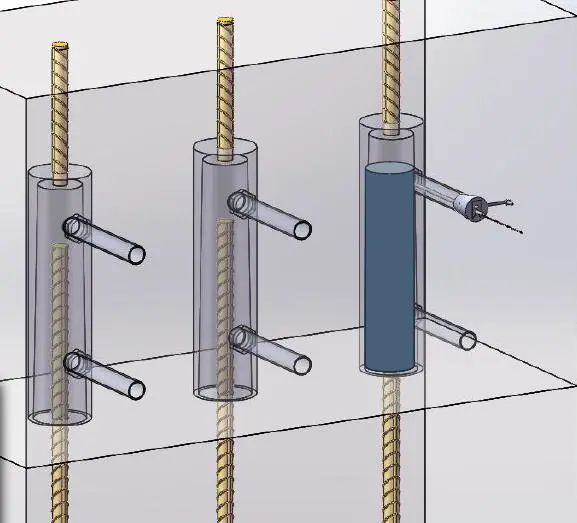

The main problems in the reinforcement sleeve grouting process are ① structural safety.

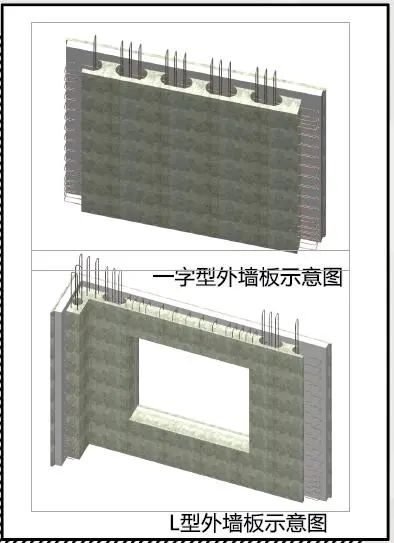

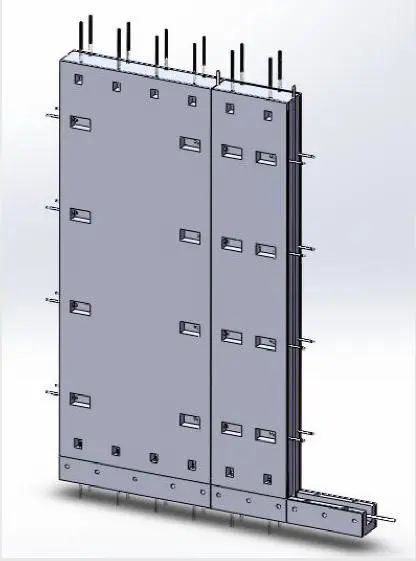

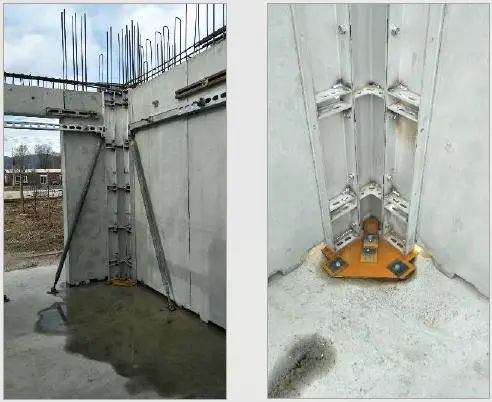

2、 Precast hollow shear wall system: EVE III, composite shear wall system (double skin wall), double skin wall connected with two precast panels in the factory, and the inner core between the two walls is reserved for post-cast concrete area.

② Construction period.

Socialization: EPC is an important way to realize professional, intensive and socialized production of engineering construction.

The integral structure is formed by lapping reinforcement and post-cast concrete in the wallboard cavity; The experimental study shows that the seismic performance of the system is basically consistent with that of the cast-in-place structure, and fully meets the requirements of the current national standards.

Considering the low-rise buildings, the vertical connection basically does not produce overturning force under the action of horizontal force, and is mainly based on shear force.

Large plate and light weight are conducive to rapid and low-cost construction.

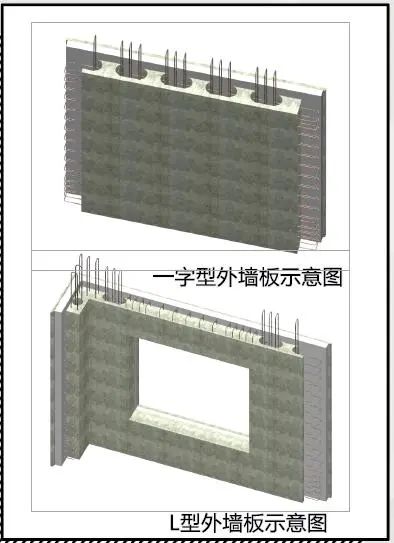

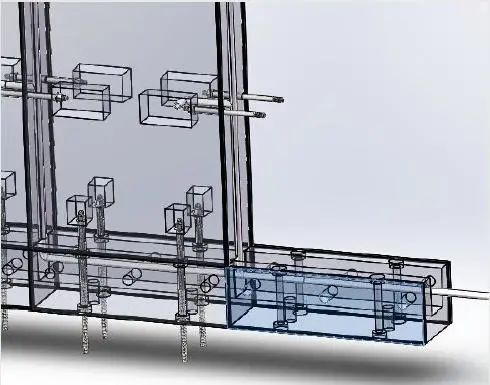

4、 The inner and outer wall panels of the longitudinal rib composite shear wall structure are patented special hollow structural wall panels, and other components are the same as the current shear wall structure.

The exterior wall still adopts the sandwich structure of “integration of structural thermal insulation and decoration”, which can make full use of the existing assembly line equipment, and use the reverse striking process to achieve the effect of fair-faced concrete, artistic concrete, and porcelain plate decoration.

There are dry goods, cases and attitudes.

Therefore, the sleeve is omitted, and the round hole joint bar grouting connection is directly used to reduce the cost and construction difficulty.

The content of building concrete and reinforcement is large, and the structural integrity is good, which can be applied to the assembly of exterior walls of underground buildings.

Source: If Xuetian BIM College has infringement, please contact to delete one.

③ Cost.

Lack of effective quality inspection means for sleeve grouting.

Industrialization: Standardized design, factory production, assembly construction and integrated decoration are the new industrial construction methods in the future.

The existing technology greatly increases the detection cost.

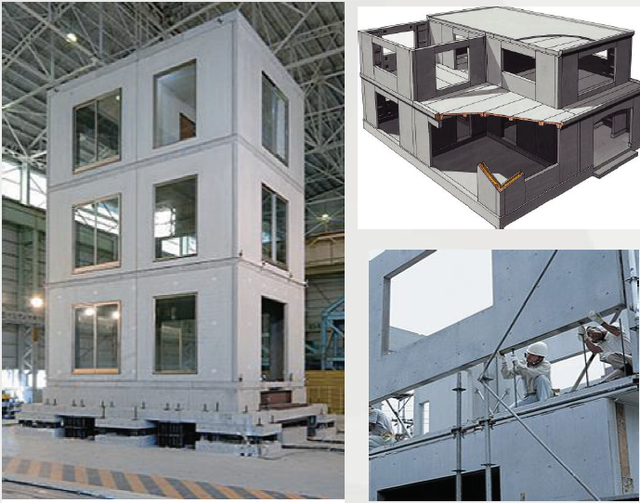

The project adopts the structural form of concrete-filled steel tube frame+composite steel plate shear wall (damper), PC external wall panel, aerated concrete external wall, steel truss floor support plate, steel stairs and integrated interior decoration system.

VIII.

Future development direction.

China’s construction industry needs to embark on the path of green, industrialization, socialization and information development in the future.

The sleeve-free steel bar lapping connection technology is used to avoid the potential safety hazard of sleeve grouting.

The exterior wall has good thermal insulation and fire resistance, and is more durable.

Click to follow the WeChat official account and click below“.

The minimum size of the inner cavity of the wallboard is more than 10cm, which is easy to compact the concrete.

Shortcomings: high cost, difficult connection operation and hidden detection.

Advantages: the upper and lower shear walls are connected in situ, and the inner and outer wall panels and the inner core are stressed as a whole; The precast part replaces part of the formwork and can be fully automated.

Greenization: Green construction is the concentrated expression of modern construction civilization and the overall improvement of the overall quality of the housing construction process.

It is urgent to solve the problem of grouting suspension in winter.

Advantages: applicable to large-diameter steel bars, widely used, mature technology; Suitable for the centralized connection of reinforcement, which can be directly connected or indirectly connected; It is convenient for on-site operation, and can adopt group grouting technology, with high construction efficiency.

80% of designers will choose to focus on the design number, which includes four major design fields: architecture/garden/interior/structure.

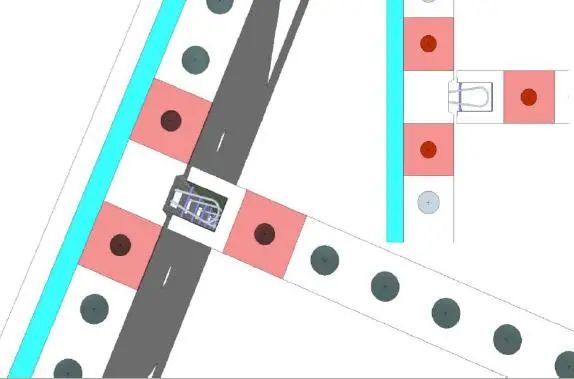

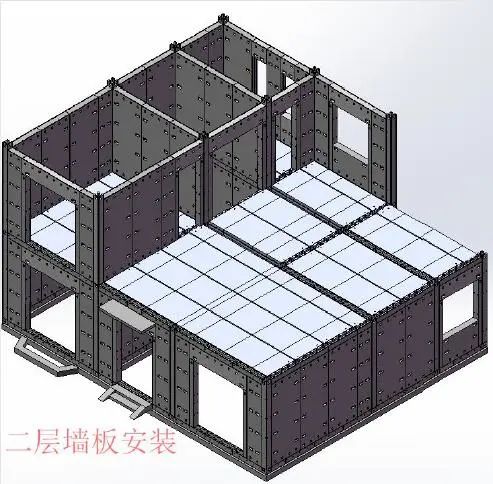

5、 Form-free dry-connection system Pinggu District precast experimental farm house project – dry-connection VI, all-bolt connection technical system VII, steel structure residential system Chengshousi B5 block directional resettlement housing project, 4 9-16 storey precast steel structure residential buildings, with a total construction area of 31685.49 ㎡.

Compared with the existing technology, under the premise of achieving the same building function, the cost of high-rise residential buildings with a prefabrication rate of about 40% can be reduced by about 200 yuan/m2.