The region will carry out large-scale industrial renovation of cement grinding

The key contents of the Opinions and Suggestions compiled by the Digital Cement Network are as follows: First, the overall idea is to carefully implement the decision and deployment of the provincial party committee and the provincial government to carry out the new round of “cage for bird, phoenix nirvana” campaign in the manufacturing industry in the province, strictly implement the national, provincial and municipal cement industry policies, take the carbon peak and carbon neutralization goal as the guide, and focus on energy conservation transformation, tax application per mu, energy efficiency and environmental protection benchmarking, Efforts should be made to reduce overcapacity, optimize industrial layout, improve industrial agglomeration, improve green production level, promote industrial intensive agglomeration, recycling efficiency, green and low-carbon development, and effectively improve the quality and efficiency of our cement grinding industry.

34), the Notice of the Ministry of Industry and Information Technology, the National Development and Reform Commission and the Ministry of Ecological Environment on Printing and Distributing the Implementation Plan for Carbon Peak in the Industrial Field (MIIT Lianjie [2022] No.

We will comprehensively promote cleaner production, strictly implement ultra-low emission standards, complete the upgrading and upgrading of dust control facilities, and ensure that the level of enterprise pollution control meets the requirements of the leading enterprise indicators in the atmospheric governance performance rating.

Continue to promote the comprehensive utilization of solid wastes such as slag, fly ash and construction waste by cement grinding enterprises, and develop circular economy.

Strictly implement the Basic Code for the Standardization of Work Safety in Enterprises (GB/T33000-2016) and the Code for the Management of Work Safety in Cement Enterprises (JC/T2301-2015), strengthen the construction of the dual prevention mechanism of risk hierarchical control and hidden danger troubleshooting and governance, strictly implement the main responsibility of work safety in enterprises, urge enterprises to carry out self-inspection regularly, and timely discover and rectify potential safety hazards.

88) and other documents, Further promote the layout optimization, structural adjustment and green and low-carbon transformation of the cement grinding industry in Huzhou City, and formulate this opinion based on the actual situation of Huzhou City.

Promote industrial transformation and upgrading, deeply integrate 5G private network+artificial intelligence+Internet plus+big data technology into cement industry raw material feeding, reaction process, quality control, pollutant distribution, energy consumption and other key links of cement production, promote automation, intelligence and unmanned transformation of the cement industry, create a number of digital workshops and intelligent factories, and effectively improve product quality, production efficiency, equipment management, safety and environmental protection.

We will establish and improve the “industry-university-research” integration platform, accelerate the research and development of key technologies, and accelerate the industrialization of innovative achievements.

The contents of the Opinions and Suggestions pointed out that in order to thoroughly implement the spirit of the Guiding Opinions of the General Office of the State Council on Promoting the Steady Growth, Structure Adjustment and Benefit Increase of the Building Materials Industry (GBF [2016] No.

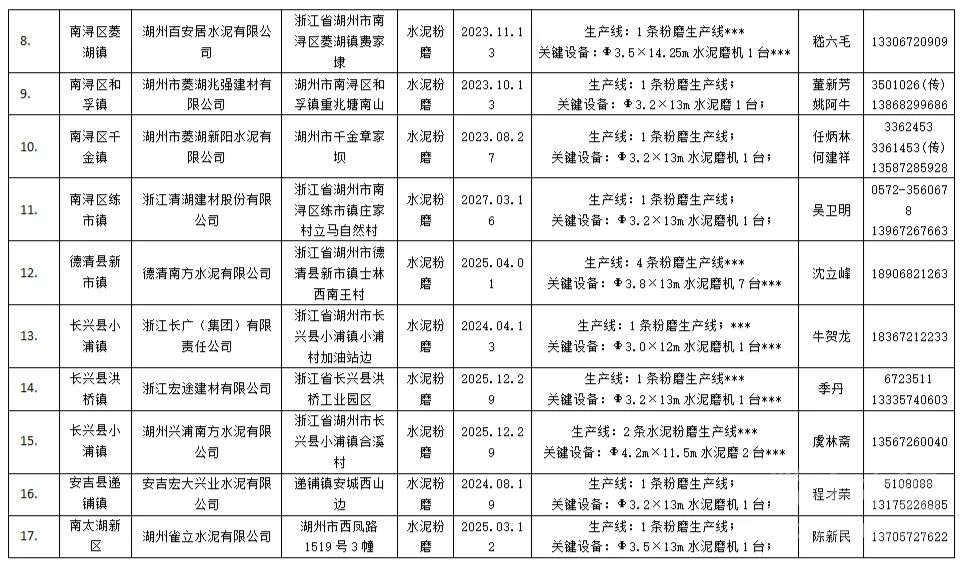

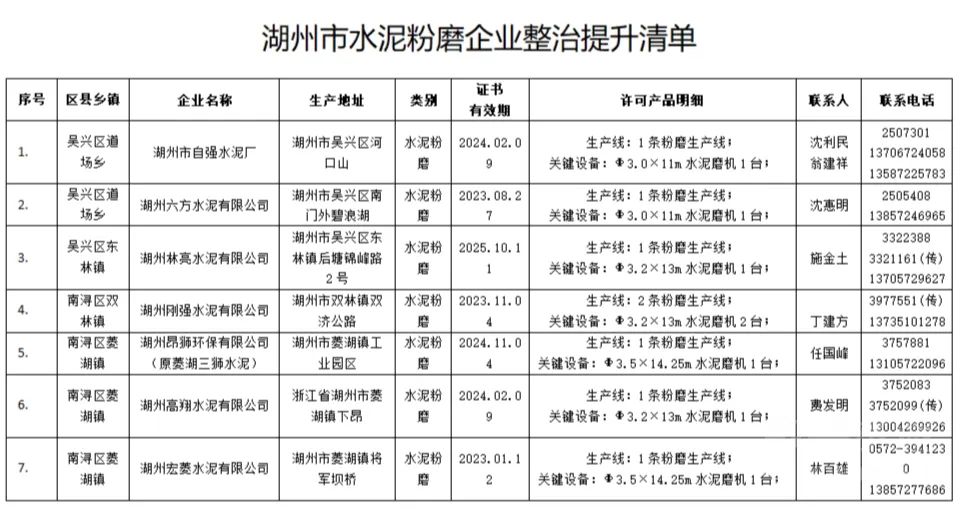

2、 The main goal is that by the end of 2025, the transformation and upgrading of the cement grinding industry in the whole city will have achieved obvious results: more than 13 cement grinding enterprises in the whole city will be closed down and reorganized, and about 600 mu of land will be freed up; Free up energy consumption space of nearly 40000 tons of standard coal; The average tax per mu reaches more than 400000 yuan/mu, and the average added value per mu reaches more than 1.2 million yuan/mu; The energy consumption per unit of industrial added value decreased by more than 17% compared with 2020; The emission intensity of major air pollutants has decreased significantly, the emission concentration of particulate matter is not higher than 10mg/m3, and the control of unorganized emission and clean transportation of bulk materials and products meet the ultra-low emission requirements; The industrial structure layout is further optimized.

At the same time, advanced technologies such as green environmental protection, solid waste utilization, energy conservation and emission reduction, and intelligent production must be adopted; The scale should reach an annual cement output of 1 million tons and above, and the mill diameter should be 3.8 meters and above; The comprehensive energy consumption per unit product of cement must reach the energy consumption limit level 1 of the Energy Consumption Quota per Unit Product of Cement (GB16780-2021); The dust removal equipment, storage, packaging, transportation and other series of control measures that meet the requirements of the Implementation Plan for Ultra-low Emission Transformation of Zhejiang Cement Industry must be equipped, and online monitoring facilities must be installed.

3、 The main task is to strictly control the new cement grinding capacity and encourage the joint restructuring of existing enterprises.

In principle, the number of cement grinding enterprises in each district (county) is not more than 1, and the total number of cement grinding enterprises in the city is not more than 7; The proportion of green building materials products has been steadily increased, the quality level and the supply capacity of high-end products have been significantly enhanced, the level of energy conservation, emission reduction and comprehensive utilization of resources has been further improved, and a number of provincial green factories have been built; Cement grinding enterprises lead the province in energy and resource utilization efficiency, intelligent, green and low-carbon production level.

On February 21, Huzhou Municipal Bureau of Economy and Information Technology of Zhejiang Province issued the Opinions and Suggestions on Widely Soliciting the Guiding Opinions on Accelerating the Improvement of Cement Grinding Industry (Draft for Comments).

Increase investment in the development of new cement and encourage the use of existing cement production lines to develop new special cement products that meet the needs of marine, port, high-speed rail, tunnel and other projects; Encourage the development of low clinker coefficient cement, new carbon fixing gel materials and other new low-carbon cement, enrich the cement product system and expand the market scope.

.

If the relevant enterprise conceals the relevant information or provides false materials to apply for the administrative license, the administrative organ may refuse to accept or refuse the administrative license.

Promote green and safe production, promote energy-saving and consumption-reducing transformation, and establish and improve the energy consumption monitoring system.

Regulate low efficiency and high consumption enterprises, strictly implement the latest environmental protection, energy consumption, safety, quality, technical equipment and other regulations and standards, irregularly carry out special inspections on legal compliance, and require enterprises that fail to meet the standards to rectify within a time limit.

We will improve the incentive and restraint mechanism, and give gradient rewards to cement grinding enterprises that voluntarily withdraw according to the withdrawal time.

Those that fail to rectify within the time limit or still fail to meet the standards after rectification will not be issued with new production licenses and will be shut down and withdrawn according to law.