Will the wind of civil construction and precast building be blocked?

Everyone likes good things, and everyone just wants to cheat the government.: At present, it seems that on-site control is indeed a problem: the biggest problem of precast concrete structures is the problem of on-site inspection means.

It has been analyzed that compared with cast-in-place structures, precast buildings reduce water, electricity and formwork losses by 20%~40%, and have obvious advantages in four sections and one environmental protection.

Fourth, the assembly building left a huge quality hidden danger, such as external wall seepage.

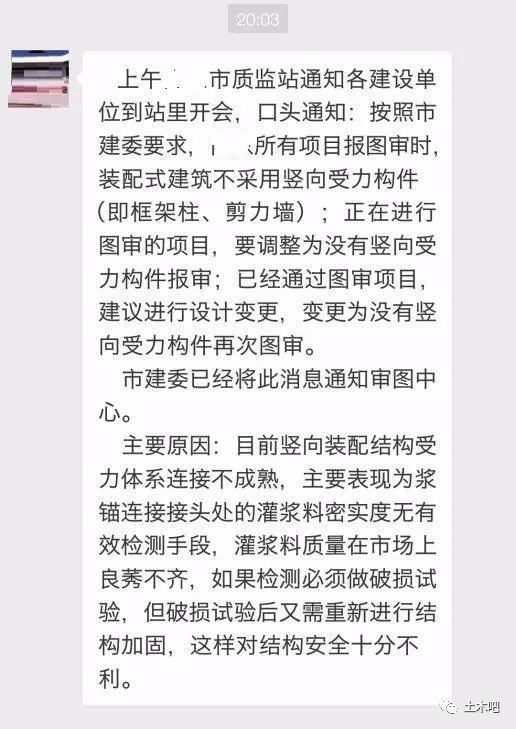

The reason is clear to everyone: at present, the connection of the vertical assembly type stress system is not mature, which is mainly reflected in the lack of effective detection methods for the compactness of the grouting material at the joint of the grout anchor link, and the grouting quality is mixed in the market.

frame columns, shear walls); For the project under drawing review, it shall be adjusted that there is no vertical stressed component to be submitted for approval; For projects that have passed the drawing review, it is also recommended to change the design and cancel the use of assembly type for vertical stressed members.

Some people think that the precast buildings will take less time than the traditional cast-in-place buildings, which is just one thing.

At present, some local governments are pushing for precast buildings, and they require the assembly rate and prefabrication rate within several rings to reach many targets.

The only advantage of precast buildings is to reduce on-site wet work, and water and electricity may not be saved.

For any technology, both feasibility and infeasibility studies should be conducted.

Parts and components of precast buildings can be processed in advance in the factory, but the installation of PC components costs more man hours.

In fact, it is unnecessary.

If a technology or process does not improve productivity, has no cost advantage, or even significantly increases costs, and the quality cannot be guaranteed, then it does not have the value of promotion.

I wonder how about the seismic performance?”? Do you have any friends who have done research in this field I agree with xxx very much.

The most correct path is to adjust measures to local conditions and let the market choose.

Some people think that the labor consumption of precast buildings is significantly reduced by 30%~50% compared with that of traditional cast-in-place buildings, so they draw the conclusion that the labor consumption is obviously superior.

According to the field survey, precast buildings cost more man hours than cast-in-situ structures, and the construction period is longer.

After investigation and research, the author found that precast buildings have no great advantages over cast-in-place structures.

China’s construction projects cannot test the self-consciousness and self-discipline of construction personnel Many frameworks in Japan are cast, and the connection method is basically similar to ours (or we use them for modification), so it is not a technology problem, but a management problem The energy consumption of concrete is mainly cement.

Third, due to the lack of craftsmanship, migrant workers have been accustomed to rough manufacturing, and can not adapt to and meet the precision requirements of precast buildings.

In fact, the total amount of labor for precast buildings will not decrease, and may still increase, but part of the workers required for the reinforcement works, woodworking formwork and concrete pouring originally constructed on site will be transferred to the precast component processing plant.

If only feasibility studies are conducted, only its advantages may be seen and its disadvantages ignored.

If the inspection means can’t keep up with it, no matter how good the laboratory system is, we don’t know what it will become.

In addition, PC installers on the construction site are newly added, which was not originally available.

Secondly, there is no standardization of domestic building components, and various specifications are ever-changing, which is tantamount to personalized customization.

▲ Click the Civil Engineering Bar to pay attention to our authoritative civil engineering expert team to build a civil engineering bar, and enter the province and city to exchange unreliable information.

In order to transform the construction and production mode and upgrade, the construction industry also needs to have realistic feasibility.

So why did foreign precast buildings succeed? Because foreign assembly technology is more mature, parts are standardized.

Assembling should not be a new topic, nor should there be too strong policy support and strong promotion measures.

If the cast-in-place structure is of poor quality, it will also cause water seepage of the external wall, but after all, it is integral cast-in-place, while the precast building is the assembly of PC components, so there are a lot of joints.

The energy consumption of on-site casting and factory prefabrication is the same! But the promotion of assembly type is under the banner of energy conservation and environmental protection! But the first problem that the structure should solve is security There are still many differences between laboratory and field control I should not be too optimistic when I went to the construction site The density check of grouting may be a problem It feels like they are all assembling for assembling! In fact, the assembly type of infilled wall is more reliable.

If the joints are not properly treated or cut corners, although there may be no problem within one or two years after completion, water seepage will certainly occur after three years, and the cost of future maintenance is quite high.

Mao Hongbin always said in his WeChat

Every splice is actually a weak point.

And these joints also affect the mechanical properties of the structure..

According to the requirements of xx Municipal Construction Commission, when all xx projects are submitted for drawing approval, the precast buildings shall not use vertical stressed components (i.e.

If the PC factory has insufficient capacity, the construction site may have to wait in line, thus delaying the construction period.

Its quality depends too much on on-site operation.

There are the following factors restricting the development of assembly in China: First, the assembly technology at home and abroad is not mature, and there are no skilled operators in this field.

After hearing this news, all the peers in the industry agreed: “For the cast type, I have always been worried about the seismic problem.

It can not be mass produced, and the recycling rate is low, so it can not reduce its marginal cost.