How to design prefabricated finished product supports and hangers

The design of prefabricated finished support and hanger requires following certain steps and requirements. The following are some main design steps: (Xiangyang Prefabricated Finished Support and Hanger Manufacturer).

1. Understanding project requirements: Before starting the design, it is necessary to understand the specific requirements of the project, including building type, structural form, seismic grade, installation space, load conditions, etc. This helps to provide clear direction and goals for subsequent design work..

2. Choose the type of support and hanger: Based on project requirements, choose the appropriate type of support and hanger, such as suspension, support, combination, etc. At the same time, factors such as the material, specifications, and anti-corrosion treatment of the supports and hangers also need to be considered..

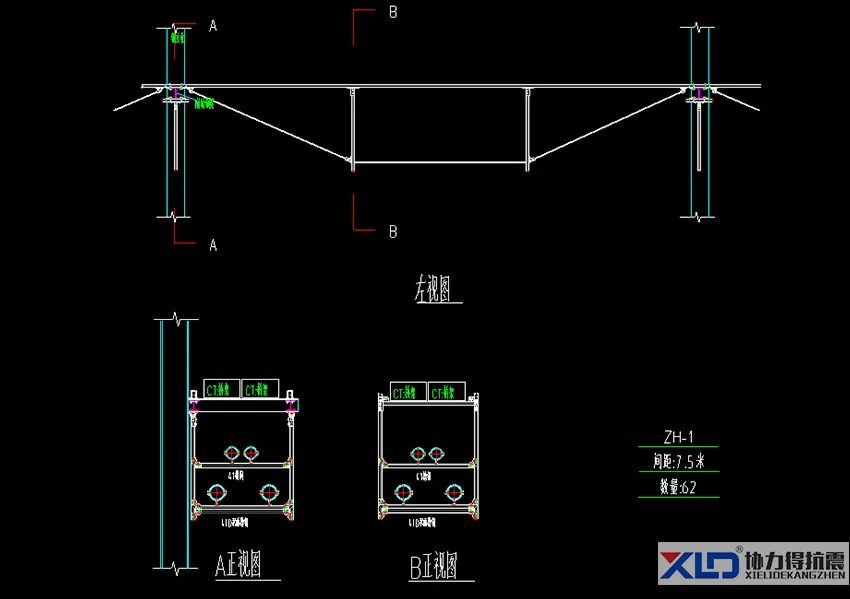

3. Determine the layout of supports and hangers: Based on the building floor plan and mechanical and electrical equipment layout, determine the layout position and quantity of supports and hangers. During the layout process, certain spacing and height requirements should be followed to ensure the bearing capacity and stability of the supports and hangers. (Xiangyang Prefabricated Finished Support and Hanger Manufacturer).

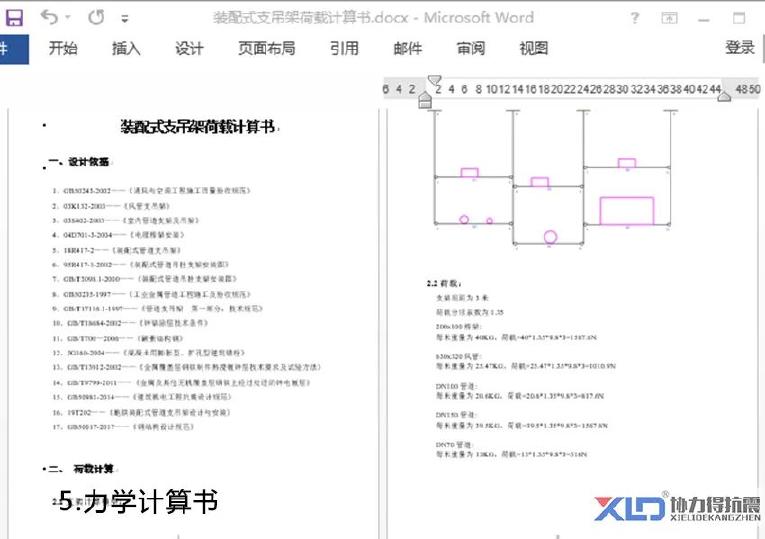

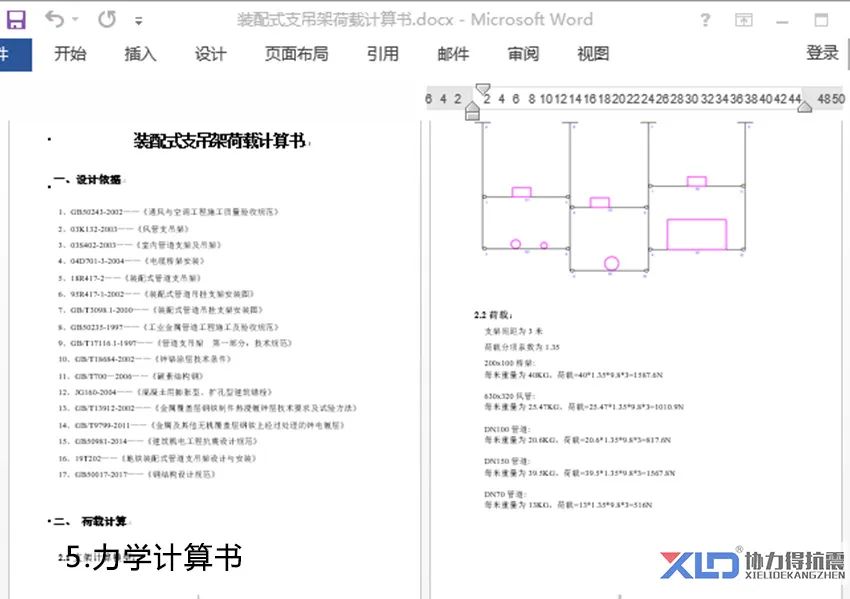

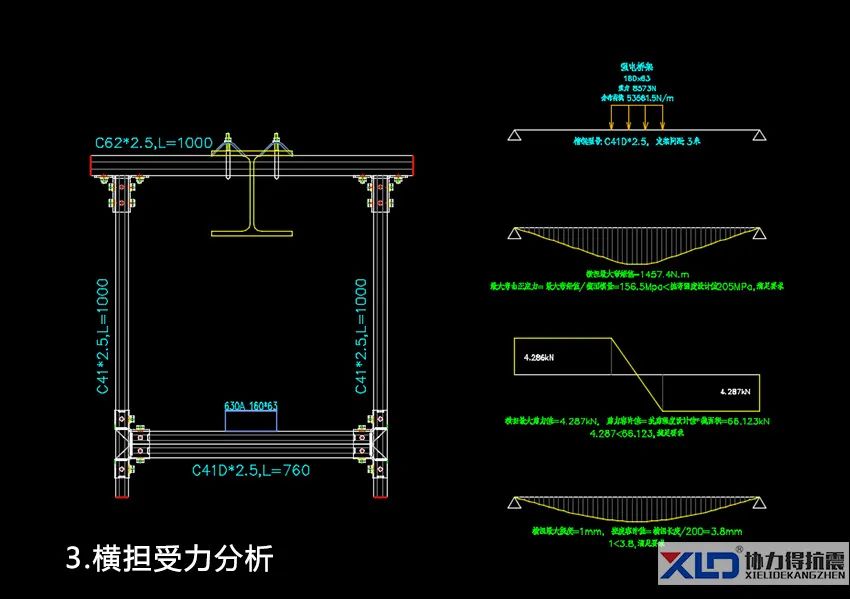

4. Perform force calculation: Based on the layout and load conditions of the support and hanger, perform force calculation, including vertical load, horizontal load, seismic action, etc. In the calculation process, relevant design standards and specifications should be followed to ensure the accuracy and reliability of the calculation results..

5. Choose connection method: Based on the type and stress situation of the support and hanger, choose the appropriate connection method, such as bolt connection, welding, clamp connection, etc. At the same time, factors such as the material, specifications, and anti-corrosion treatment of the connectors also need to be considered..

6. Draw construction drawings: According to the above design steps, draw the construction drawings of supports and hangers, including floor plans, elevations, node details, etc. When drawing construction drawings, certain drafting norms and standards should be followed to ensure the quality and readability of the construction drawings..

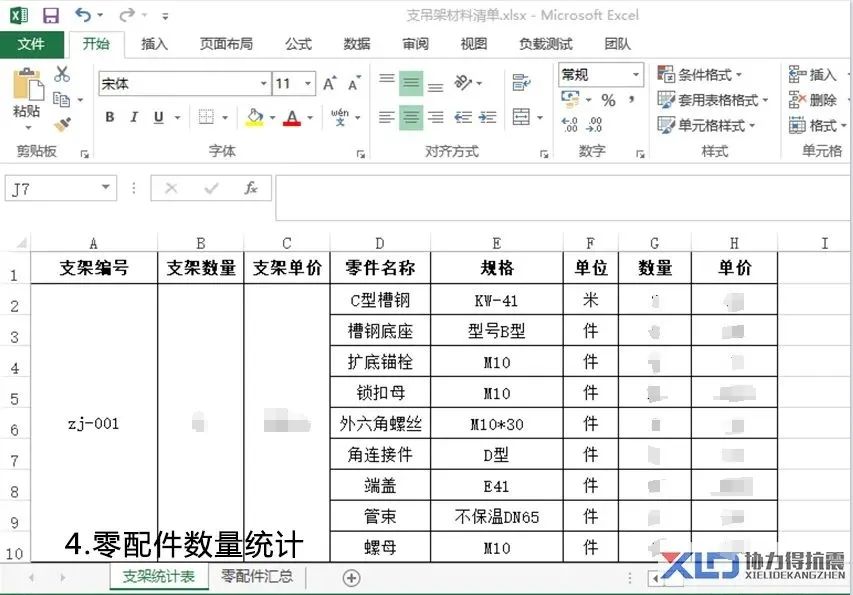

7. Preparation of Material List: Based on the construction drawings, prepare a material list for supports and hangers, including supports and hangers, connectors, installation accessories, etc. When preparing the material list, a certain amount of loss and reserve should be considered to ensure the smooth progress of the project..

8. Conduct design review: After completing the design work, the design results should be reviewed, including internal and external reviews. Internal review is conducted by the manufacturer or design team, mainly to check whether the design results comply with relevant standards and specifications, as well as whether they meet project requirements. External review is usually conducted by the owner, supervisor, or other relevant units to ensure the compliance and rationality of the design results. (Xiangyang Prefabricated Finished Support and Hanger Manufacturer).

Through the above steps, the design of prefabricated finished support and hanger can be completed. In practical operation, manufacturers should adjust and optimize according to the specific situation of the project to ensure the smooth progress of design work..

Hubei Xielide Engineering Technology Co., Ltd. is a multifunctional and diversified modern technology enterprise specializing in seismic support, prefabricated support and hanger, seismic support and hanger, and pipe gallery seismic support. It integrates design, communication support, prefabricated support, finished comprehensive support and hanger, U-shaped hanger, embedded groove, BIM consulting production, sales, and installation. The product is widely used in nuclear power plants, power plant renovation, high-speed rail construction, airport expansion, national large-scale construction projects, etc!.