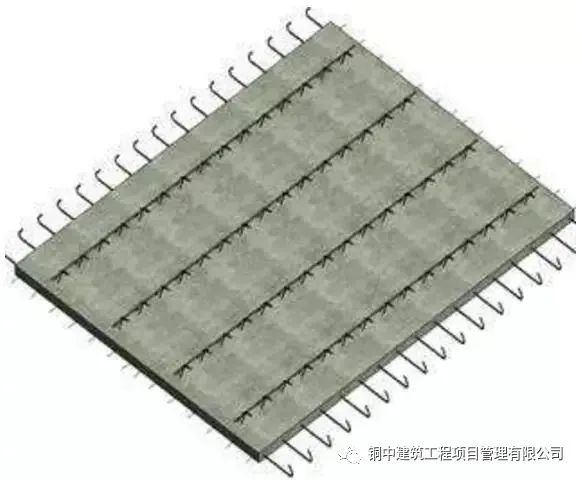

Share precast concrete building technology – laminated floor

the “close joint” between the bottom plates) and integral joint (there is post cast concrete belt between the bottom plates).

When the span of precast base plate is greater than 4m, or the longitudinal reinforcement used for the upper part of cantilever plate and adjacent cantilever plate is anchored in the cantilever layer, truss reinforcement or other forms of shear structural reinforcement shall be set.

When precast prestressed bottom slab is adopted for precast bottom slab, reliable measures to control reverse arch shall be taken.

Ensuring the common bearing and coordinated stress of the concrete on the upper and lower sides of the composite surface is the key to the design of precast concrete composite floor slab, which is generally realized by the roughness of the composite surface and the shear structural reinforcement at the interface.

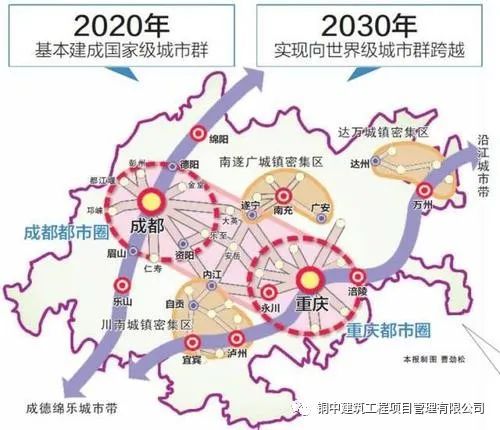

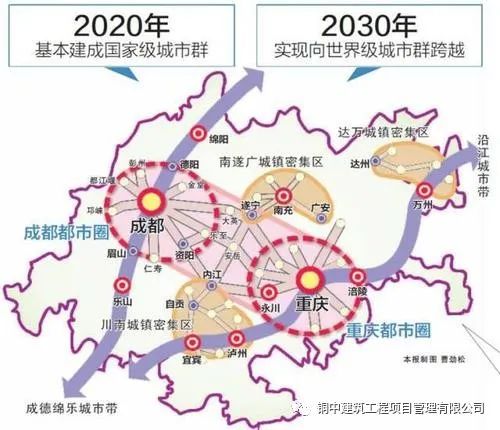

01 concrete composite floor slab is classified according to the specific stress state.

Concrete composite floor slab is divided into unidirectional stress and bidirectional stress composite slab according to the specific stress state.

03 scope of application: floor structure in various houses, especially suitable for residential and various public buildings.

02 technical standard 1 The design and structural requirements of precast concrete composite floor slab shall comply with the relevant requirements of the current national standards gb50010-2010 code for design of concrete structures, jgj1-2014 technical code for precast concrete structures and GB / t51231-2016 technical standard for precast concrete buildings; The fabrication, construction and temporary design of precast base plate shall meet the relevant requirements of code for construction of concrete structures (gb50666-2011); The construction acceptance shall comply with the relevant requirements of gb50204-2015 code for acceptance of construction quality of concrete structures.

Classification of precast bottom slab precast bottom slab can be divided into precast concrete bottom slab and precast prestressed concrete bottom slab according to the type of stressed reinforcement: when the precast concrete bottom slab adopts non prestressed reinforcement, truss reinforced concrete bottom slab is mostly used to enhance stiffness.

Disclaimer: some of the content (including text, pictures, videos and other materials) published on this public platform comes from the Internet,.

The thickness of precast base plate shall not be less than 60mm, and the thickness of post cast concrete laminated layer shall not be less than 60mm.

The precast prestressed concrete bottom slab can be prestressed concrete flat slab, prestressed concrete ribbed slab and prestressed concrete hollow slab.

5.

3.

4.

7.

The composite plate with reliable support shall be set, and the precast components will not deform affecting the internal force under the weight of post cast concrete and construction load, which shall be calculated according to the design of overall flexural components.

Design principle: when the span is greater than 3m, the precast bottom plate should adopt truss reinforced concrete bottom plate or prestressed concrete flat plate.

The joint surface between the precast base plate and the post cast concrete laminated layer shall be set with rough surface, the area shall not be less than 80% of the joint surface, and the concave convex depth shall not be less than 4mm; The precast bottom plate of truss reinforcement can be set, and the natural rough surface can be set.

Whether reliable supports are set in the construction stage determines the design and calculation method of laminated plates.

When the span is greater than 6m, the precast bottom plate should adopt prestressed concrete ribbed bottom plate and prestressed concrete hollow slab.

6.

The design atlas of relevant national building standards includes 15g366-1 truss reinforced concrete composite slab (60mm thick bottom slab), 14g443 precast ribbed bottom slab concrete composite slab and 06sg439-1 prestressed concrete composite slab (50mm and 60mm solid bottom slab).

The concrete strength grade of precast concrete base plate shall not be lower than C30; The concrete strength grade of precast prestressed concrete base plate shall not be lower than C40, and shall not be lower than C30; The concrete strength grade of post cast concrete laminated layer shall not be lower than C25.

According to the connection mode, the butt joint can be divided into separate joint (i.e.

The precast base plate can be divided into “bearded reinforcement” and “beardless reinforcement” according to whether there is an extended reinforcement.

2.

When the thickness of the composite floor is greater than 180mm, the prestressed concrete hollow composite slab should be adopted.

For the unsupported laminated slab, the weight of secondary forming pouring concrete and construction load affect the internal force and deformation of the member, which should be designed and calculated according to the laminated member under two-stage stress.