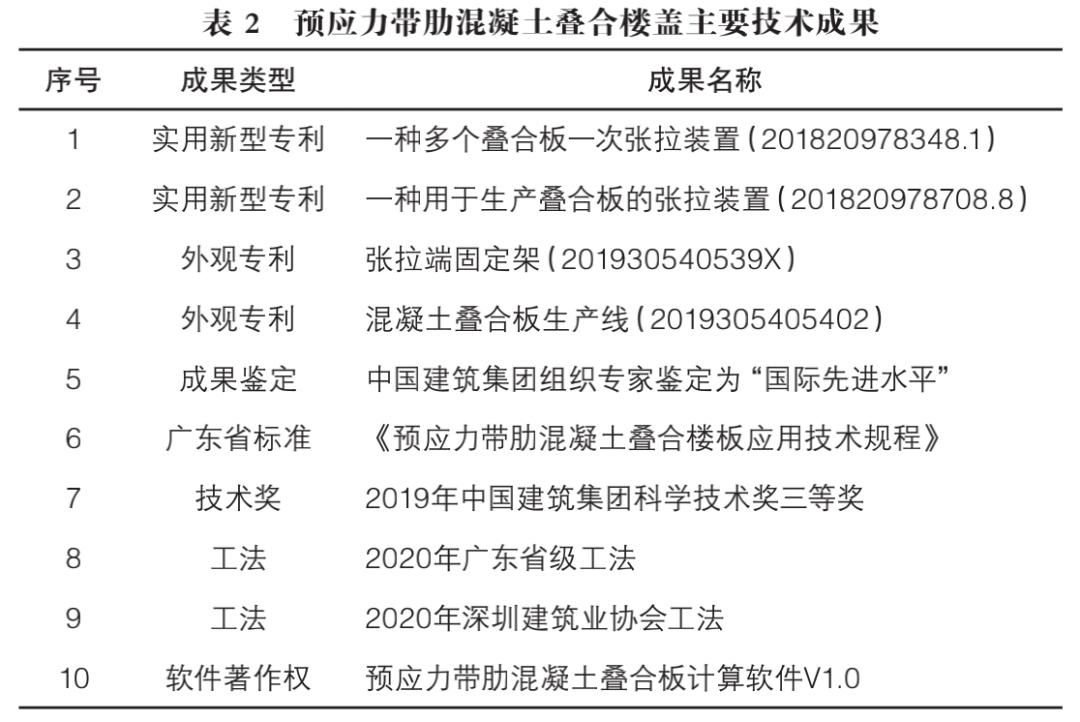

Research and application of key technologies of precast prestressed concrete composite floor system

Fig.

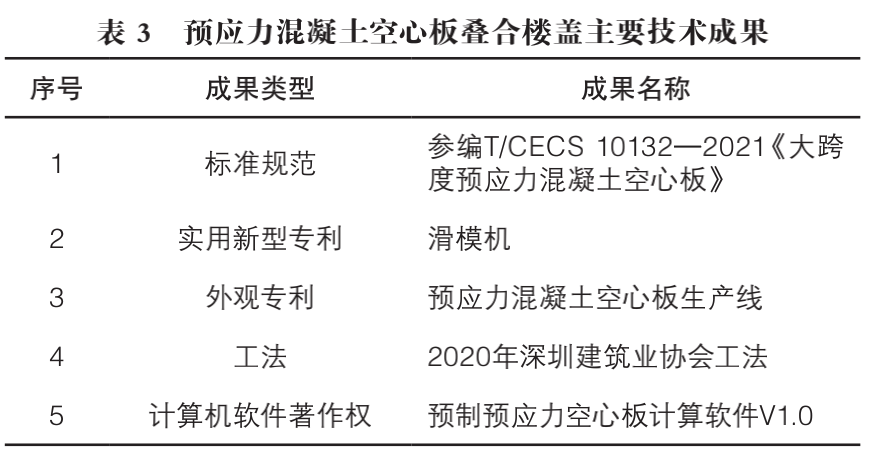

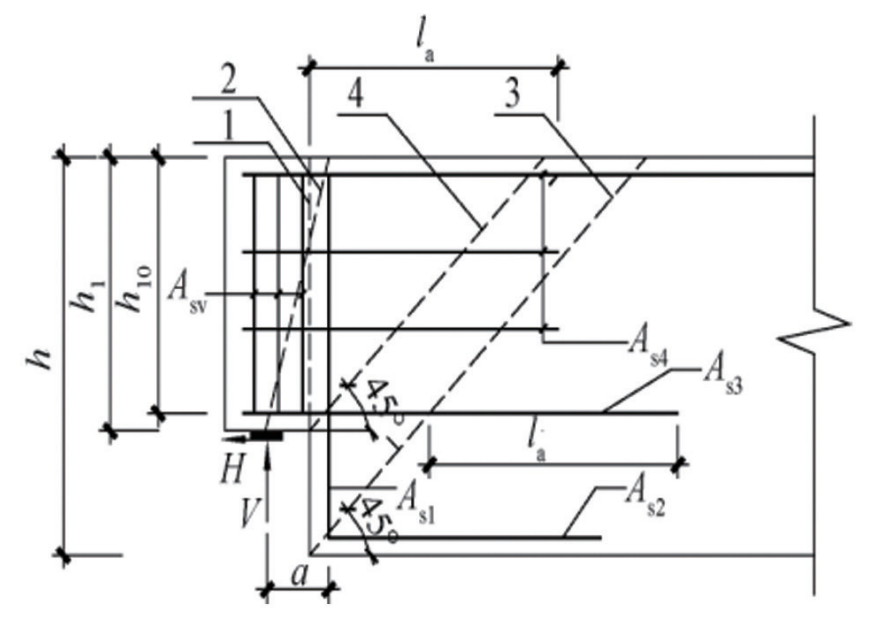

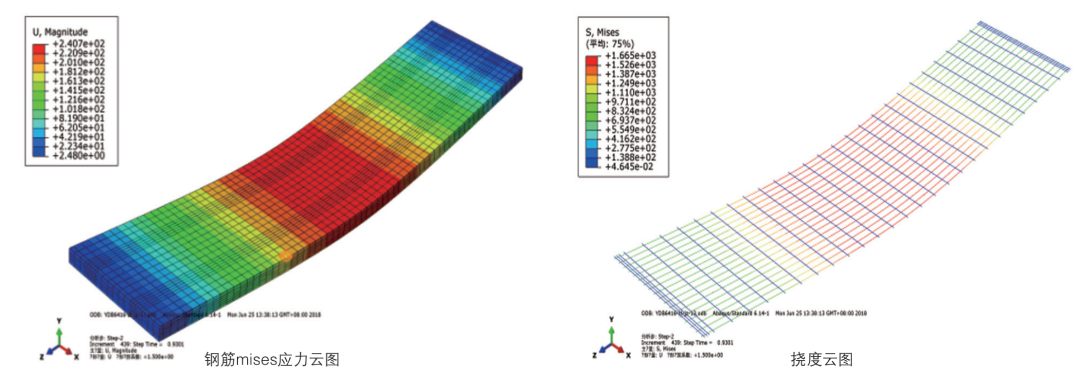

The analysis and calculation of the crack resistance, deflection and reverse arch value of the bottom plate are carried out.

Some finite element simulation results are shown in Figure 3.

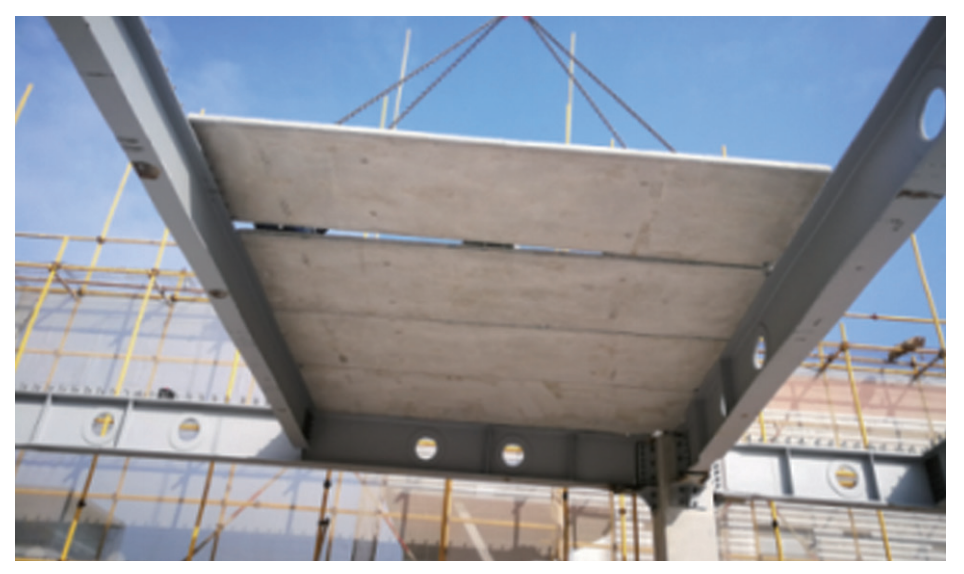

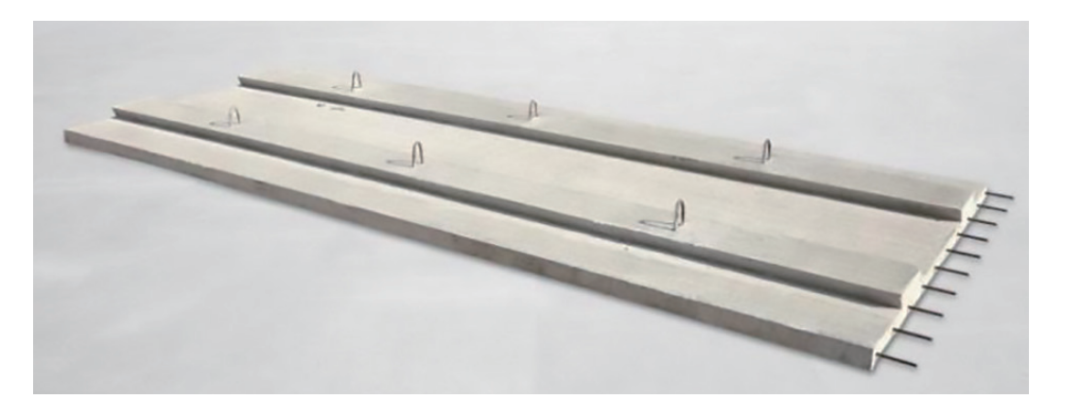

The precast prestressed ribbed concrete base plate is precast in the factory, with no reinforcement in the lateral direction and prestressed reinforcement in the longitudinal direction.

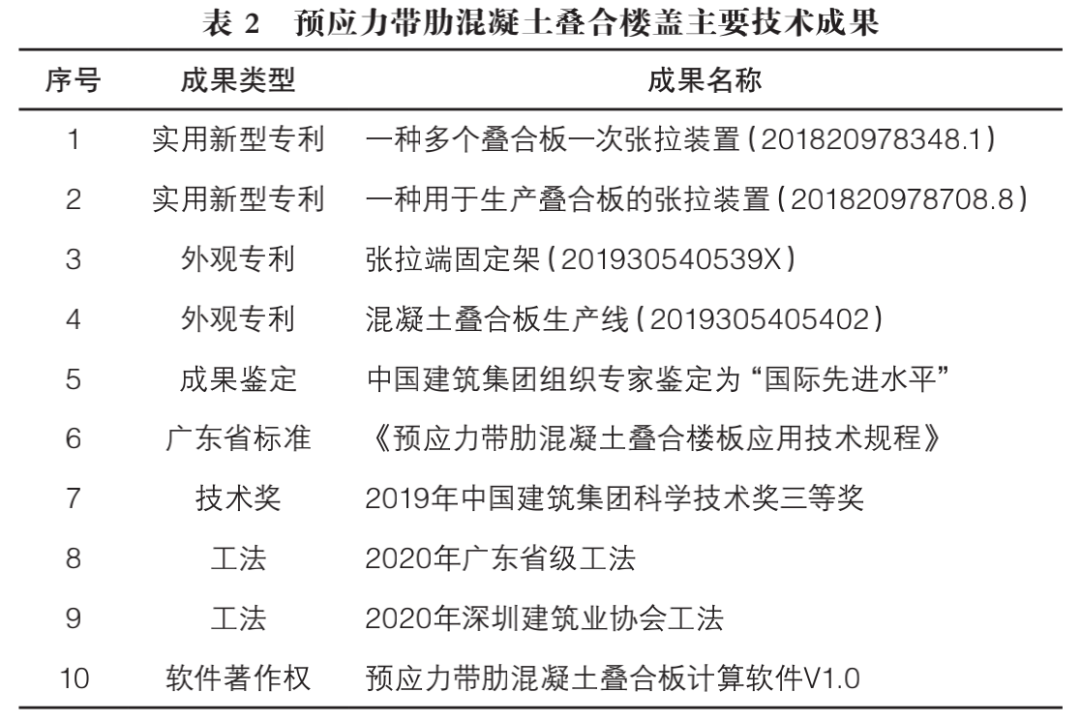

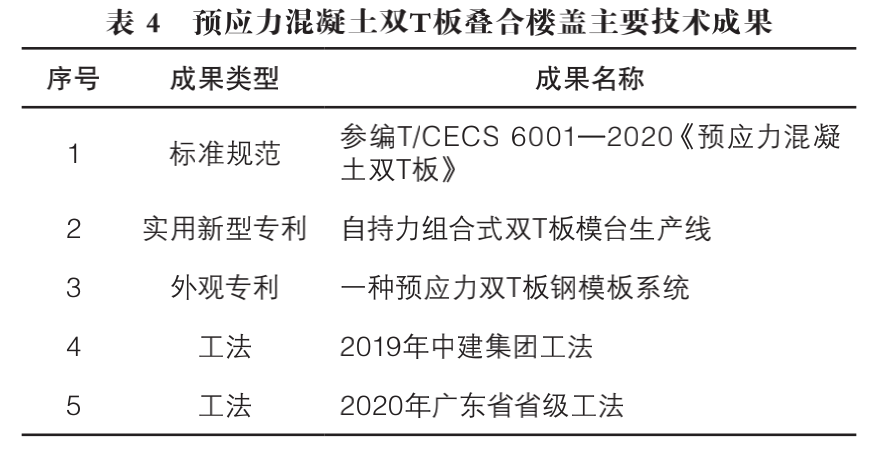

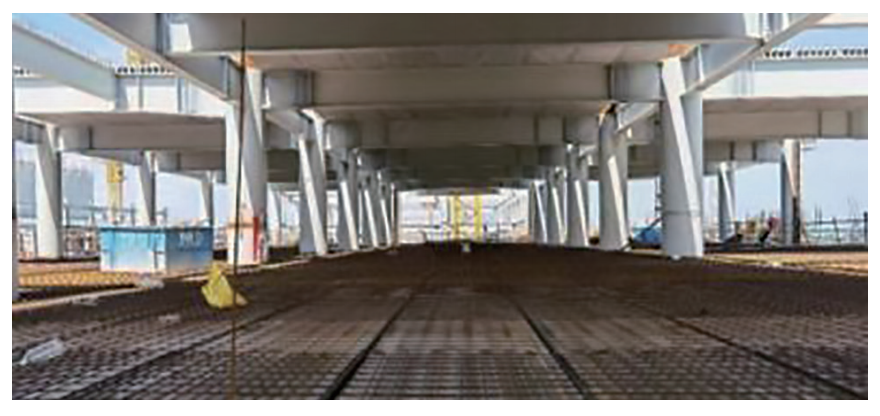

The research of these three kinds of prestressed concrete floors has been successfully applied to many projects of precast buildings from the building and structural system to the key technologies of design, production and construction, and has achieved good economic and social benefits.

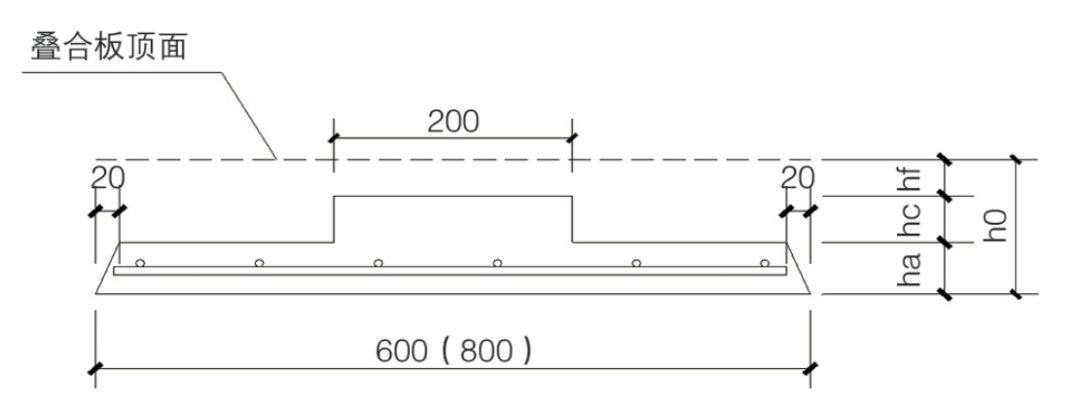

2 standard screenshot of precast prestressed composite slab (unit: mm) finite element analysis of single slab: prestressed reinforcement adopts high-strength prestressed steel wire, with a diameter of 7mm or 9mm.

Combined with the development of precast buildings, through the combination of factory precast prestressed technology and precast building laminated plate technology, technological innovation in the field of housing construction will obtain great economic and social benefits.

Fig.

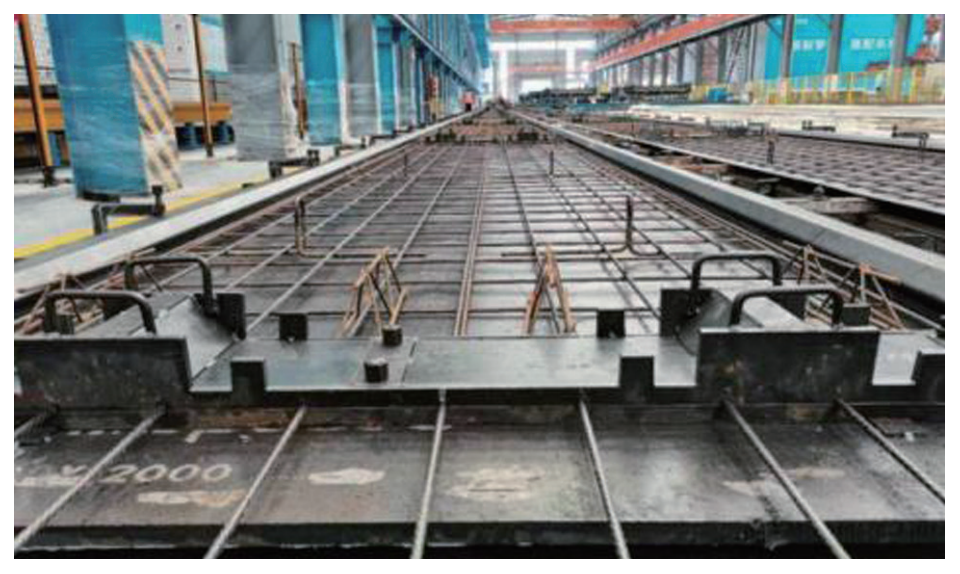

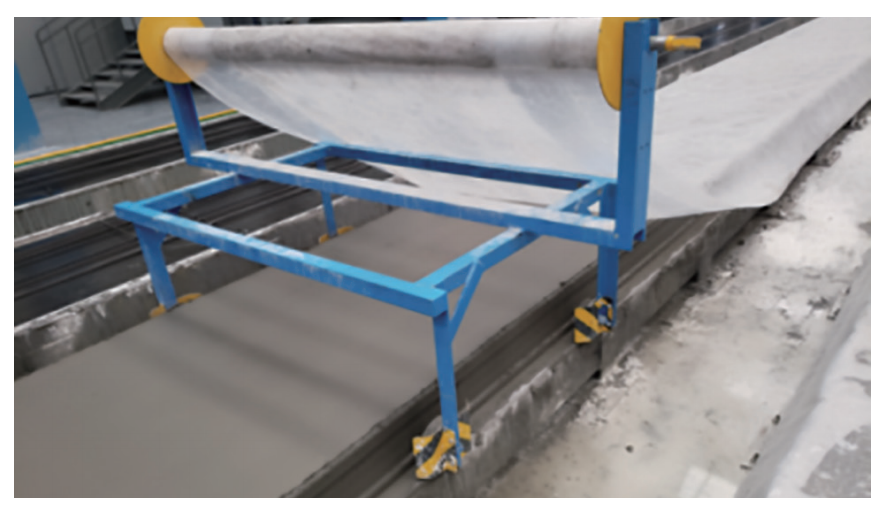

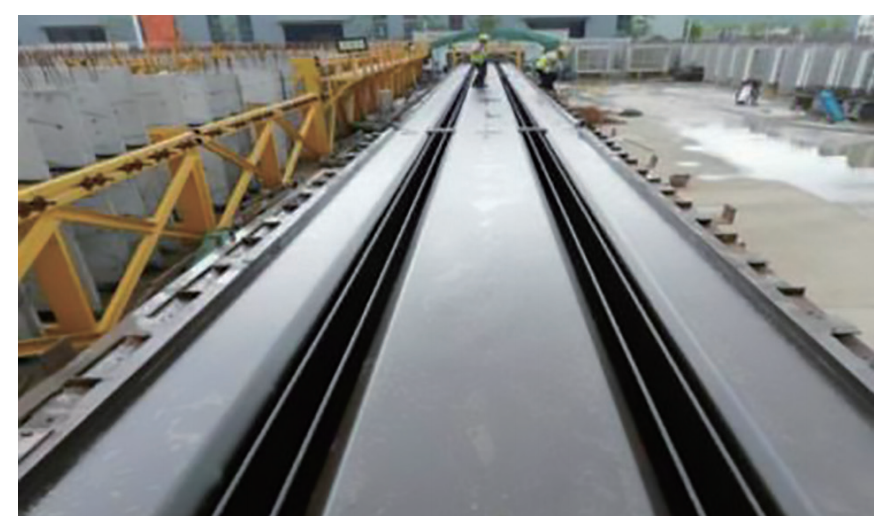

1.2 research on production technology long line flow operation technology: long line platform is adopted, with a length of 120m and a width of 2400 and 3500mm.

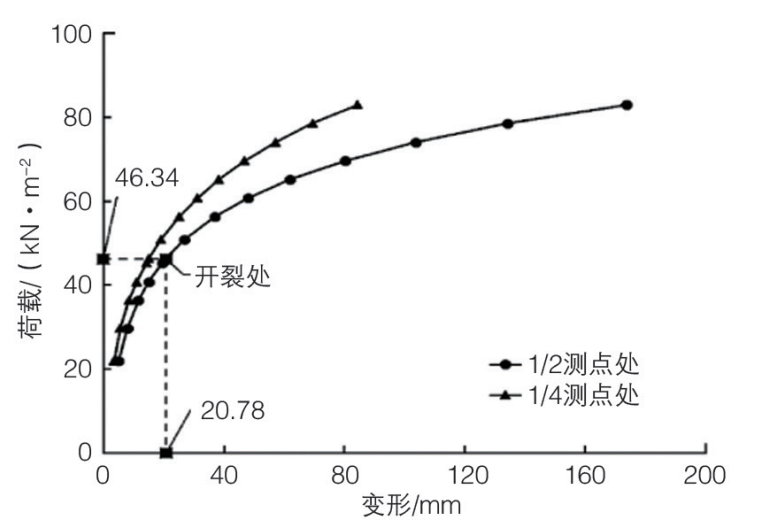

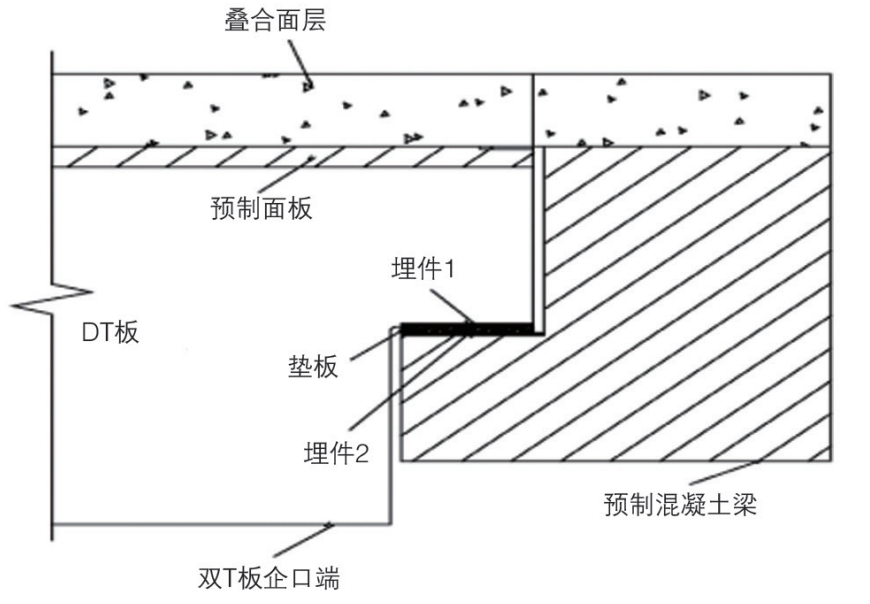

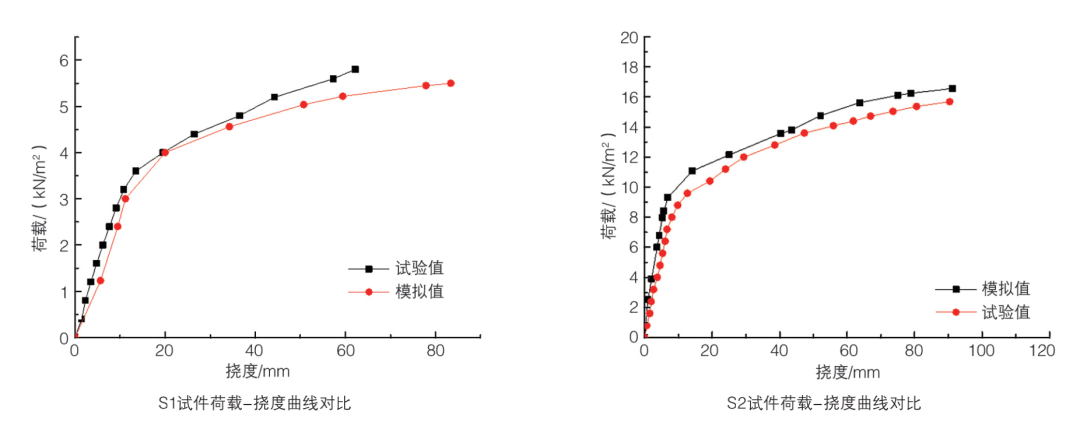

4 Schematic diagram of laminated plate joint structure (unit: mm) 1.1.3 experimental research the flexural capacity test of one precast ribbed base plate specimen (S1) and one prestressed laminated plate specimen (S2) is designed and compared with the relevant modeling analysis of finite element to verify the accuracy of prestress application and selected parameters in the model.

The comparison of load deflection curves of S1 and S2 specimens under test and simulation conditions is shown in Figure 5.

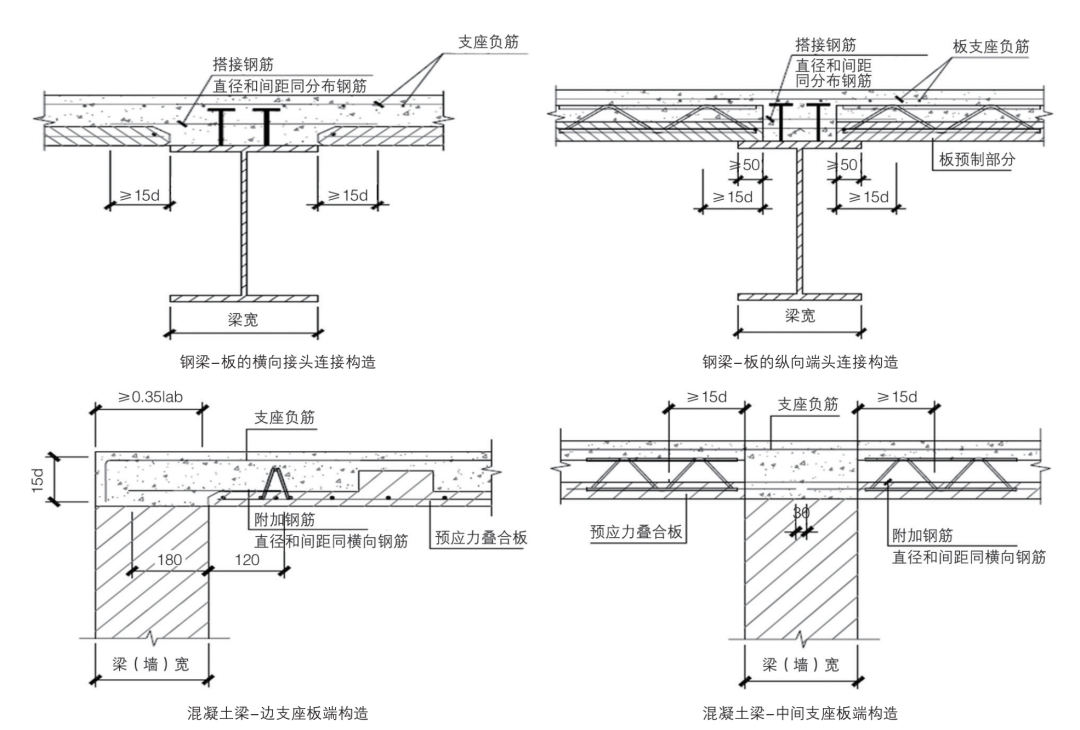

Figure 3 finite element simulation results of laminated plate specimen 1.1.2 node design according to different structural forms, design suitable structural nodes to meet the stress requirements of different structures.

Reinforced truss concrete composite floor is a kind of floor system that is widely used at present.

Because the precast composite floor has relatively small impact on the building structure, it is easy to achieve the goal of “equivalent cast-in-place” specified in the specification through superposition.

01 prestressed ribbed concrete composite floor prestressed composite floor is composed of precast prestressed ribbed concrete base plate and upper post cast concrete composite layer, which has the advantages of good integrity, strong crack resistance, high bearing capacity, large span, good economy and so on.

Prestress technology has great advantages in solving the bearing capacity, cracks, deflections and construction costs of horizontal structures, and has been widely used in municipal, railway and Bridge fields.

The section size is shown in Figure 2.

As shown in Figure 6..

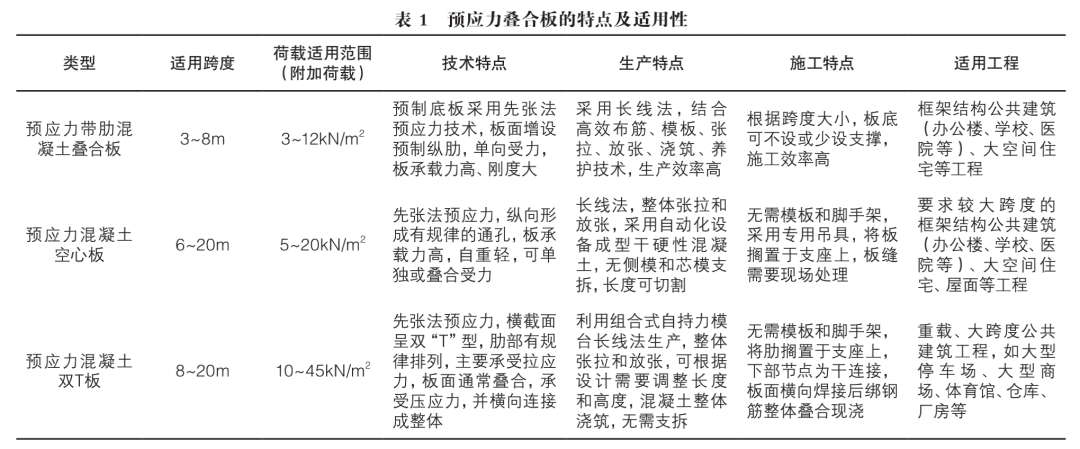

See Table 1 for the characteristics and applicability of the three precast slabs.

The thickness of the base plate is usually 50mm.

However, due to the influence of building functions, seismic fortification, industrial supporting facilities and other factors, many projects are split in this way, the implementation efficiency is reduced, the construction cost is increased, and the effect is not ideal.

Form a flow process around the formwork, including formwork cleaning, reinforcement arrangement, prestressed tensioning, concrete pouring, curing, loosening and hoisting.

This system has been applied abroad, and has played a good role in many kinds of construction engineering applications.

In the actual market, most of the composite floors are designed according to the cast-in-place structural system, and then “split” into precast and cast-in-place composite floors.

The upper part is provided with ribs, which can resist the reverse bending moment formed by the prestressed reinforcement and the compressive stress when there is construction or permanent load.

Mechanical calculation: the preset maximum span is 9.0m, the slab width is 600mm and 800mm as the foundation size, and the precast rib width is 200mm.

5 load deflection curve test and simulation comparison of ribbed laminated plate.

This paper introduces three kinds of high-performance prestressed concrete floors developed by the company: prestressed ribbed concrete composite floor, prestressed concrete hollow slab composite floor and prestressed concrete double-T slab composite floor.

Water bath maintenance circulation pipeline is set under the platform.

Research and application of key technologies of precast prestressed concrete composite floor system in recent years, China has vigorously promoted the development of precast buildings, the scale of the industry continues to grow, and various precast building technologies and products emerge in endlessly.

At the same time, in the evaluation rules in most parts of China, the precast composite slab can calculate the prefabrication rate according to the projected area, so it is widely used as the “standard” technology and product of precast buildings.

Fig.

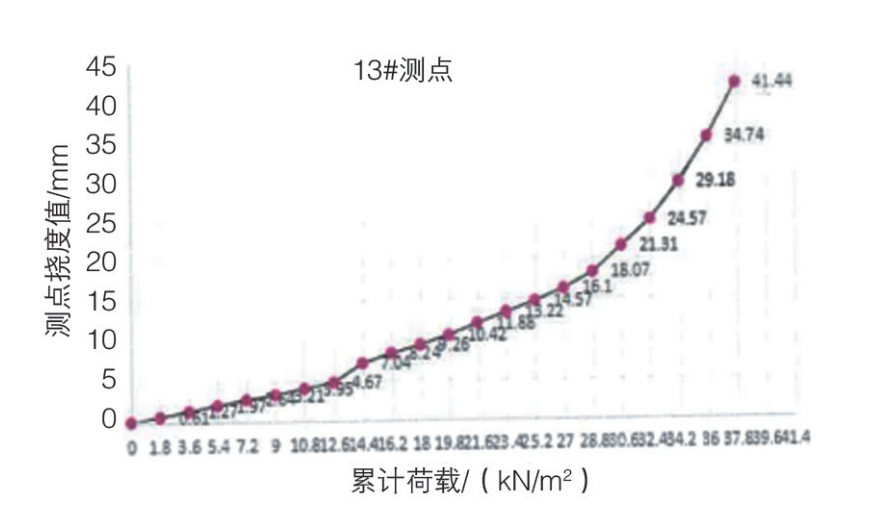

The test results show that: (1) the laminated plate specimen is not cracked under normal service load, and the deflection meets the specification limit; (2) Under long-term load, the final total deflection at the midspan is 23.6% of the midspan deflection of simply supported plates at both ends under the same load of the same specification, and the overall large plate shows the characteristics of two-way stress; (3) Under the normal service load, the concrete on the top of the slab and floor is not cracked and damaged; The maximum tensile stress of prestressed reinforcement is far less than the tensile yield strength of reinforcement, which meets the design requirements; (4) The results of finite element numerical simulation are in good agreement with the experimental results, which better reflect the real stress characteristics of laminated plates.

This system is closest to the traditional cast-in-place floor, and it can realize low difficulty switching from the perspective of design and construction.

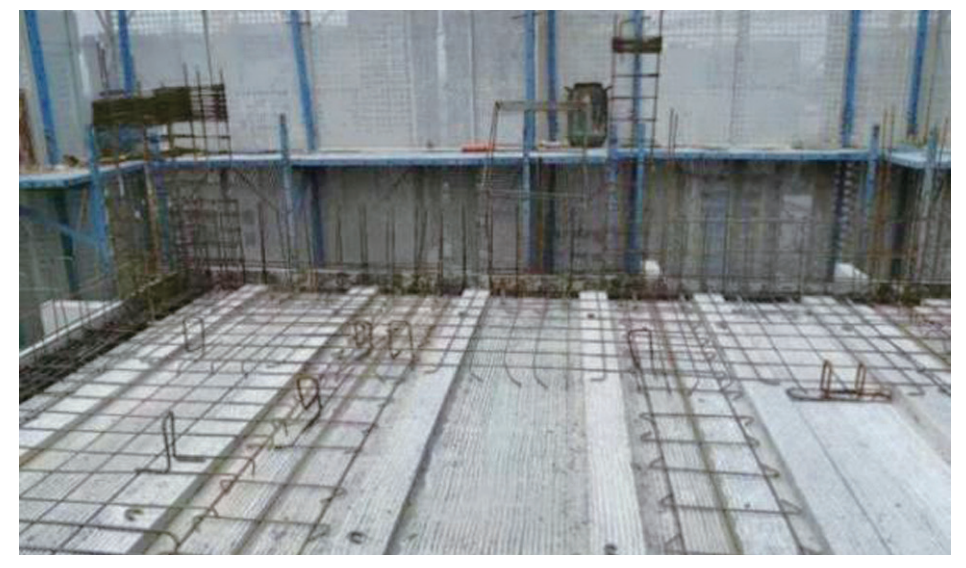

According to the shear requirements of the plate end, set the shear structure reasonably, such as steel beam studs, shear truss reinforcement at the plate end, etc., as shown in Figure 4.

The precast prestressed ribbed laminated plate bottom plate is shown in Figure 1.

The bottom plate is precast in the factory, and the upper part is cast-in-place.

Figure 1 precast prestressed ribbed composite slab base plate 1.1 design research 1.1.1 theoretical research first, clarify the boundary conditions of structural calculation, and determine the building span and the most unfavorable conditions for use; Secondly, the stress state of precast components and laminated structures in different stages of production, transportation, installation, use and so on is analyzed, and the reasonable reinforcement and prestress value are designed through mechanical calculation; Finally, numerical analysis and simulation are carried out.

The test adopts the uniform loading method to study the deflection change, crack characteristics, ultimate bearing capacity and other mechanical properties of prestressed ribbed composite plates, and determine the failure load value.