In the double-carbon era, precast buildings usher in the “second spring”

2.

High production efficiency Most precast buildings are directly produced and assembled in the factory, which can not be affected by the natural environment.

At the same time, due to the artificial or intelligent production conditions, the construction period is also controllable, which greatly improves the production efficiency.

Click the blue letter to pay attention to our precast buildings, which can also be called precast buildings, that is, transfer the traditional construction process to the factory, which is a modern mode of production.

It has successively issued several enterprise standards, such as Plant Ecological Board, Thermal Insulation Integrated Exterior Wall Panel and Roof Panel for Building, and has been rated as the “leader of enterprise standards” by the China Society of Technology and Economics, It has also obtained the Certification for the Application of Building Energy-saving Technology Products in Shandong Province and obtained the building application license.

First, due to the reduction of on-site wet operations, including pouring, welding and cutting operations, the problems of dust, noise, light pollution, water pollution, construction waste and so on have been effectively reduced.

4.

Western precast architecture began in the industrial revolution and has now developed to a relatively mature and perfect stage.

Straw composite board has breathing function, can purify indoor air, comfortable and livable, and can achieve zero energy consumption of buildings with the use of solar energy resources.

The components of the precision, high quality and good assembly construction are poured, maintained and demoulded in the factory, and have a more stable production mode and quality assurance measures compared with the on-site construction.

Compared with traditional buildings, precast buildings have the characteristics of energy conservation and environmental protection.

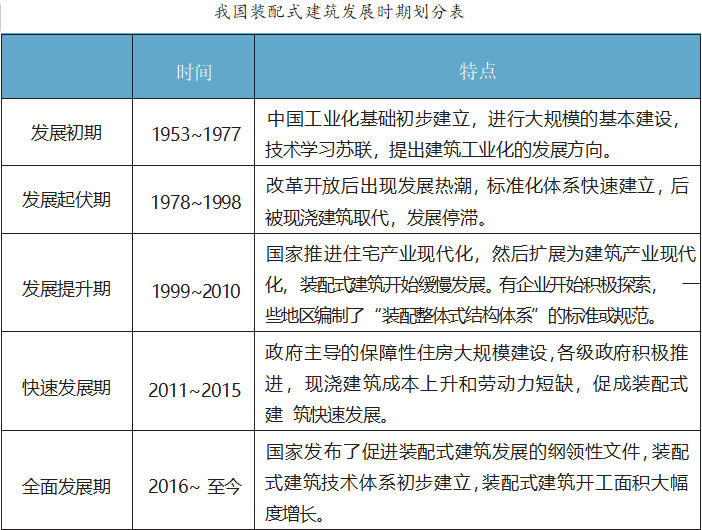

The precast buildings in China started in the 1950s, and have entered a period of comprehensive development after experiencing the stages of creation, development, fluctuation and rapid development.

Jintian straw composite board can be widely used in concrete frame, steel structure ordinary buildings and precast buildings below 100m, and wood structure precast buildings below 10 floors, with the assembly rate of more than 80%.

There is no dust, noise and construction waste in the whole construction process; The applied steel can be recycled 100%, reducing the carbon emission of buildings.

Most importantly, the application of green environmental protection material – straw composite board has ushered in the “second spring of business” of precast buildings in the context of the double-carbon era! Jintian Technology, the leader of straw comprehensive utilization, truly realizes the “turning waste into treasure” of straw.

Advantages of precast buildings: 1.

The weight of the house built with straw composite board is only one third of that of the house with the same area built with reinforced concrete, which is convenient for transportation and safe and efficient for construction.

With the continuous promotion of the transformation and upgrading of China’s construction industry, the realization of new urbanization development, the implementation of energy conservation and emission reduction strategies and other important measures, precast buildings have become the building form vigorously developed in China.

In recent years, the straw composite building materials and building system of Jintian Science and Technology has been applied to more than ten projects, such as the construction of the China International Solar Decathlon Competition house, the Beijing University of Technology ecological intelligence test room, the Yantai Laishan District green intelligent building demonstration project, and the Kunyu Mountain farmhouse tourism house…

In order to enable the development of the industry, Jintian Technology has prepared and issued the industry standard of Straw Composite Wallboard and the group standard of Straw Wallboard for Building, which are the requirements of the leader’s standard evaluation.

3.

Production cost reduction The manufacturing mode of factory production and assembly line production used in precast buildings can greatly reduce the production cost of building components.