Application of precast toilet in precast decoration

SMC chassis is molded by large machinery at high temperature, with high degree of mechanization, guaranteed quality, good anti-skid performance, good thermal insulation performance and no cold feeling.

We adhere to the original intention of “improving the construction environment and practicing green assembly” to create a happy space for human health, ecology and human settlement.

Alu functional integrated toilet # Alu medical aluminum bathroom system adopts flexible customized waterproof chassis and multi finish texture wall panel selection to meet the needs of multiple styles.

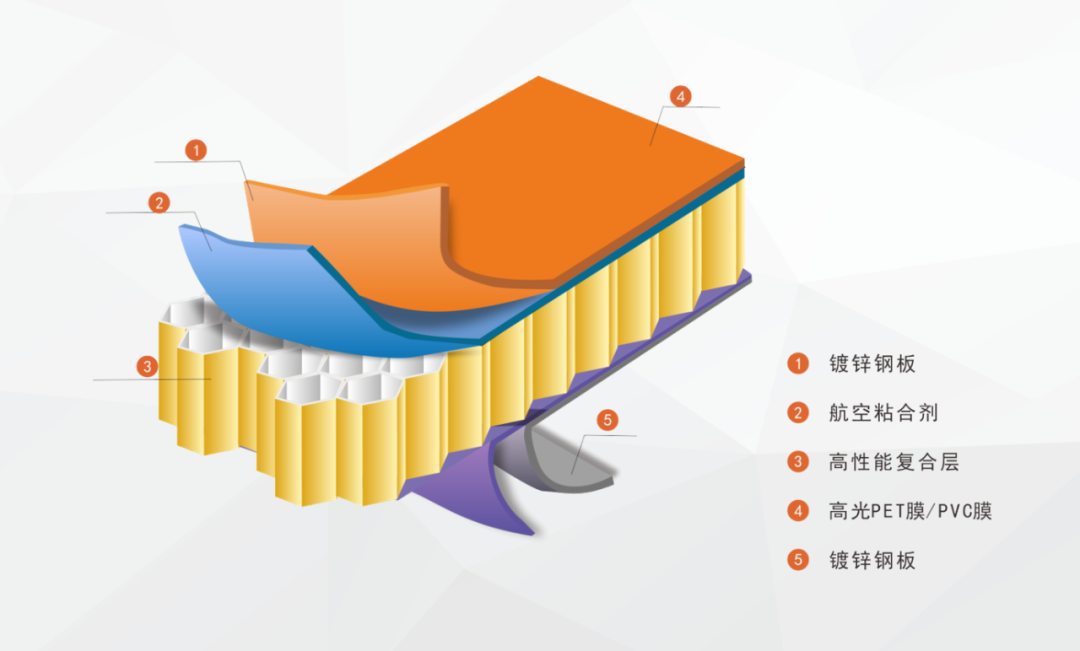

The utility model has the advantages of high intensity, good sound insulation effect, stable texture, rich colors and various patterns, which can well meet the needs of consumers.

It is environment-friendly, pollution-free, corrosion-resistant, easy to process and form, and has the original strength of the steel plate.

No leakage, no need for waterproof: the chassis of the assembled toilet is formed at one time by the CNC machine tool, with high precision and good stability.

How to further reduce product costs, improve product quality and meet the needs of users for diversity and practicability is the key to its recognition by consumers.

It is a steel plate with organic coating.

Generally, it takes only two workers 4-8 hours to complete the assembly, which greatly reduces the construction period and operation difficulty, greatly reduces the decoration waste, and plays a great role in environmental protection.

SMC (sheet moulding compound), an aviation composite composed of chemically thickened unsaturated polyester resin, filler and glass fiber reinforcement.

3.

2.

SMC wallboard has the advantages of light weight, corrosion resistance and long service life; Good heat insulation performance, high density, smooth surface, no micropores, easy to clean, no dirt, and effectively inhibit bacterial reproduction.

The high quality, low energy consumption and low pollution of the precast toilet are in line with the concept of sustainable development advocated by the state; Moreover, with the all-round development of domestic precast buildings and the increasing demand of customers for fine decoration and delivery, precast sanitary ware will usher in great benefits at the policy level, and the industrial prospect is very broad.

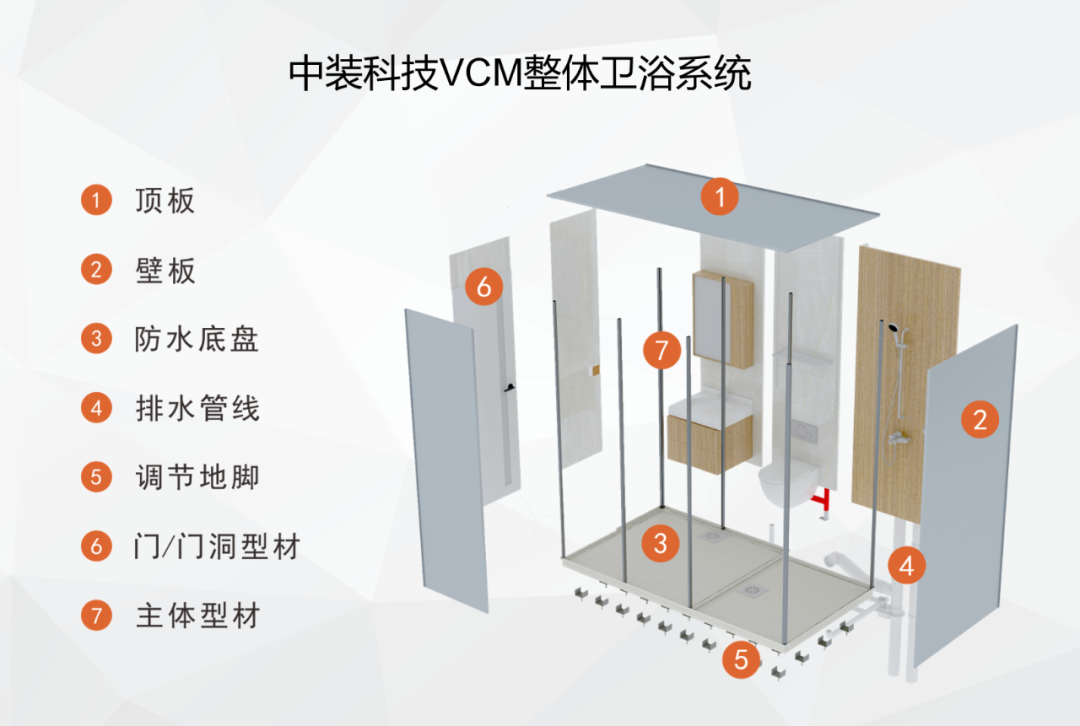

It creatively realizes the separation of bathroom functions, the integration of internal and external walls, no main light lighting, and the row of micro falling plates on the same floor.

Smart manufacturing factory # Zhongzhuang technology actively responds to the national green construction policy, innovates the research and development of assembled decoration product system, introduces professional equipment production lines, and creates a physical and digital factory; The regional layout assembly integration center integrates a complete set of matching parts installation packages such as partition system, integrated kitchen and bathroom system and dry process ground overhead system, so as to provide users with good, fast and provincial solutions.

As a technologically advanced assembly technology enterprise, we realize value-added for owners, expand happy space with science and technology, improve the construction environment, and create a sustainable green construction industry modern ecological service platform.

VCM integral toilet: VCM is steel plate composite material.

Source: Zhongzhuang technology, the copyright belongs to the original author-.

Super durable: the cast toilet has compact material and smooth surface, which can effectively inhibit the breeding of bacteria and make the toilet space lasting.

As an important part, precast toilet is also more and more widely used in precast buildings.

Zhongzhuang technology cast bathroom case ▼ comparative analysis of cast toilets with different materials ▼ cast toilets are mainly divided into four categories according to materials, namely SMC integral bathroom, VCM color steel plate integral bathroom, ALU functional integrated bathroom and thin backing integrated bathroom.

Zhongzhuang technology is a green building industrial assembly technology enterprise, which is committed to the research, development and application of integrated internal space solutions.

The advantages of the precast toilet are} clean and dry: the precast toilet adopts the arc corner design, and there is no dead angle in all directions; The surface of the waterproof plate has a good running water slope, and the drainage is rapid; No ponding and moisture absorption, easy to clean, and keep the toilet dry.

Therefore, from the State Council to local governments, they are vigorously developing precast buildings and constantly improving the construction assembly rate.

It is suitable for high-end hotels, medical care and elderly care and boutique houses.

1.

As the transformation of traditional construction methods, precast buildings are conducive to comprehensively improve the construction quality and overall construction level, and improve the comprehensive quality and performance of buildings; It is conducive to promoting energy conservation and emission reduction in the construction industry, protecting the environment, reducing carbon emissions, reducing dust and noise pollution, improving the urban environment and promoting the construction of ecological civilization.

Convenient installation: the precast toilet is constructed by dry method without the construction materials such as sand and cement used in the traditional toilet.

During installation, only screws, adhesives and other materials are required.

The overall price of SMC toilet is relatively cheap, which is suitable for ordinary hotels, hospitals, elderly care projects and just needed houses.

It fundamentally eliminates the quality problems such as water leakage and leakage caused by manual work in the traditional toilet, and truly achieves no water leakage.

By means of integrated design, industrial production and modular integrated assembly technology, the full dry operation of the inner space environment is fully realized to meet the development and operation needs of high efficiency, low cost, environmental protection, safety, sustainability and fast return.