Detailed explanation of many pictures! How to apply Bim in precast building design?

Moreover, the system design is simple, and the workers’ hands-on speed and formwork turnover speed are very fast.

2.

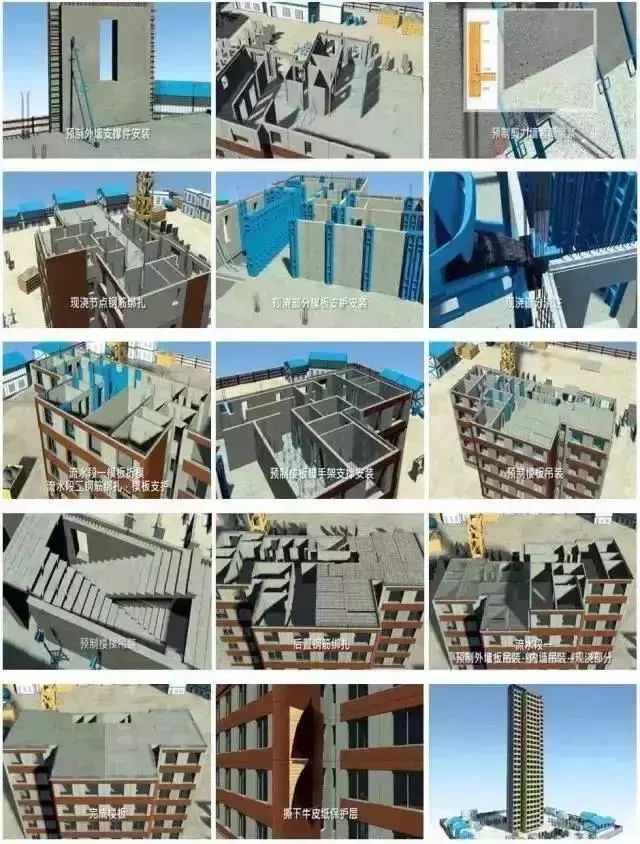

Collision detection 4 Construction simulation of complex nodes rehearses complex parts and key construction nodes in advance through construction simulation, so as to increase workers’ familiarity with the construction environment and construction measures and improve construction efficiency.

The automatic production of machinery can be realized only by inputting BIM information data into the equipment.

The component processing drawing design uses the BIM model to express the information of building components.

The component processing drawing is directly completed and generated on the BIM model, which can not only clearly convey the two-dimensional relationship of traditional drawings, but also clearly express the complex spatial section relationship.

1.

Component processing drawing component production simulation 2 The digital manufacturing of precast components is realized through cam.

Precast building is a systematic and integrated building with “five in one” of design, production, construction, decoration and management, rather than a building with “traditional production mode + assembly”.

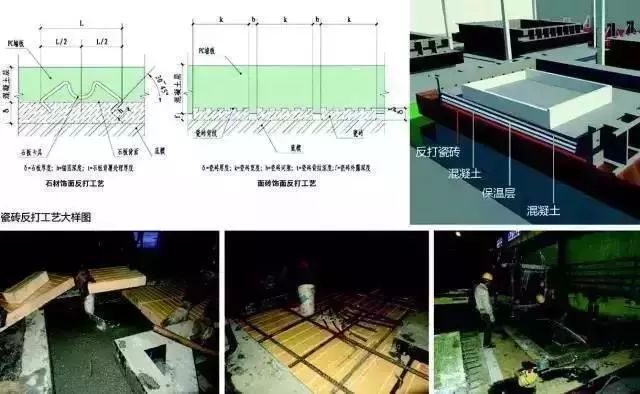

Visual design of exterior wall panel 3 BIM component disassembly and optimization design the aluminum formwork system is simple and convenient to assemble, with an average weight of about 20kg.

The reinforcement that meets the design requirements is automatically cut, formed and welded (bound) in the factory to form a standardized reinforcement mesh.

With the help of industrialized and mechanized production mode, centralized and large-scale production equipment is adopted.

Predict in advance whether the control method and construction arrangement of the main construction of the project are balanced, whether the overall plan and site layout are reasonable, and whether the process is correct, and can be optimized in time.

It is completely handled and assembled manually without the assistance of any mechanical equipment.

Optimal processing of exterior wall panel quantity Figure 3 The first mock exam of BIM is BIM design.

The assembly construction with traditional design, construction and management mode is not building industrialization.

The core of precast building is “integration”, and BIM method is the main line of “integration”.

Skilled installation workers can install 20-30 square meters per person per day, greatly saving labor costs.

At the same time, it can also concentrate the discrete two-dimensional drawing information into one model, which can more closely realize the coordination and docking with the prefabrication factory.

This digital construction method can greatly improve the work efficiency and production quality.

The 3D information model is used as an integrated platform, which is suitable for the collaboration of different majors at the technical level.

BIM model also includes building material information, process equipment information, cost information, etc., which can be used for data analysis, so as to achieve a higher level of collaboration among various disciplines.

For example, the commercialized production of reinforcement mesh has been realized.

3.

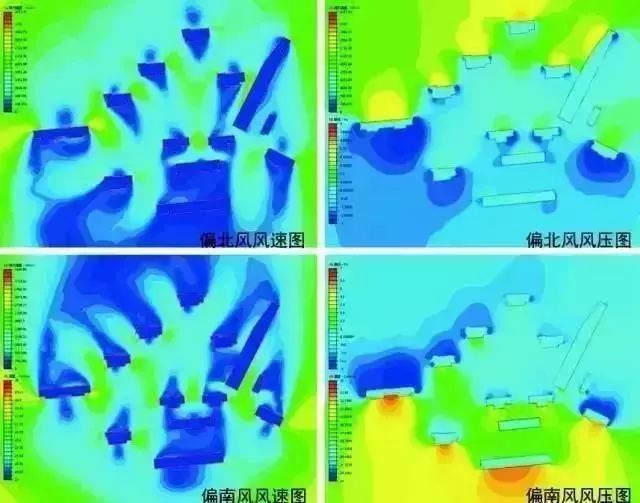

Collaborative design – collision check 4 BIM performance-based analysis can help designers adjust design strategies, achieve green goals and improve building performance through the analysis and Simulation of project sunshine and projection.

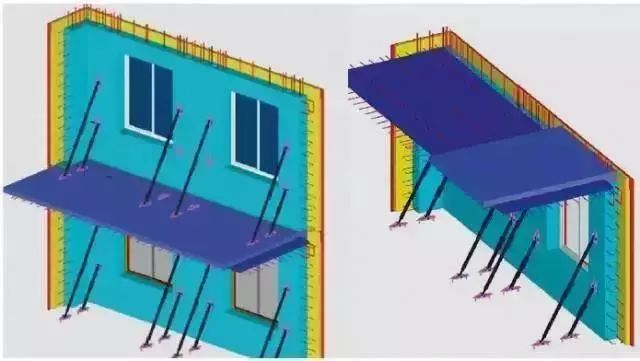

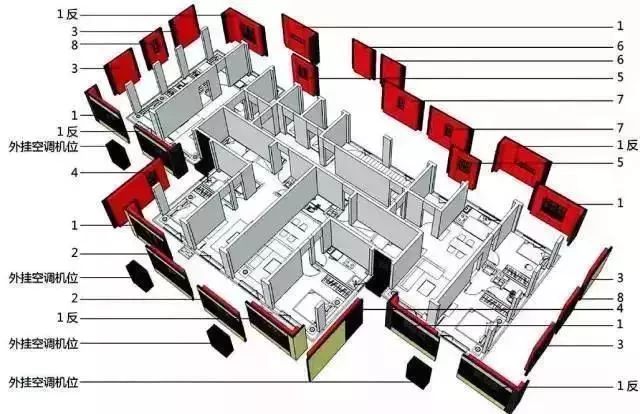

For example, the collision detection of various components in precast components and the potential staggered collision between floor heating pipes and electrical pipelines.

01 – Bim and standardized design – 1 The establishment of standardized BIM component library} the typical feature of precast buildings is the use of standardized precast components or parts.

The design of precast buildings should adapt to its characteristics.

If we can get through the collaborative bottleneck between design information model and factory automation production line, the realization of cam will be just around the corner.

03 – Bim and assembly construction – 1 Construction site organization and process simulation write the construction schedule into the BIM information model, and integrate the spatial information and time information into a visual 4D model, which can intuitively and accurately reflect the construction process of the whole building.

CFD flow field simulation Ecotect # 02 – Bim and factory production – mainly analyze from two aspects: which is more economical to rent or buy aluminum formwork; Cost comparison of aluminum formwork, wood formwork and large steel formwork.

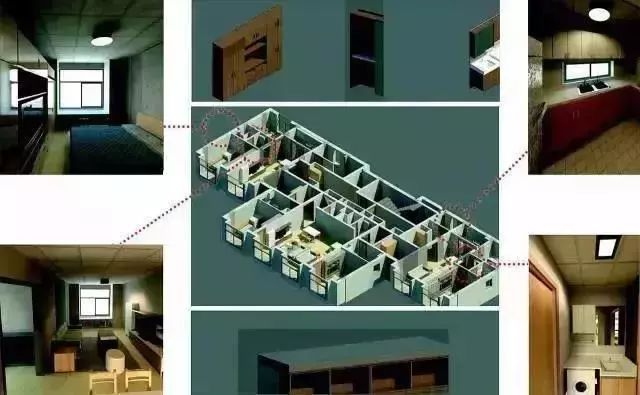

Hardcover product library construction 2 Visual design through the convenience of visualization for indoor rendering, can ensure the indoor space quality and help designers refine and optimize the design.

Construction process simulation 2 Construction and installation training through virtual construction, installation and construction management personnel can clearly know the assembly composition of precast buildings, avoid the understanding deviation caused by two-dimensional drawings, and ensure the progress of the project on schedule.

Construction simulation collision detection through collision detection analysis, we can collect and correct the “mistakes, omissions, collisions and defects” that are not easy to detect in the traditional two-dimensional mode.

Through the establishment of BIM component library of precast buildings, the number, types and specifications of BIM virtual components should be continuously increased, and the standardized precast component library should be gradually constructed.

This main line connects the whole process of design, production, construction, decoration and management, serves the whole life cycle of design, construction, operation and maintenance and demolition, can describe various system elements digitally, virtually and informatized, realize the new application of information collaborative design, visual assembly, interaction of engineering quantity information and node connection simulation and inspection, integrate the whole construction industry chain and realize the whole process and all-round information integration.

Integrating the standardized design in the decoration stage into the scheme design stage can effectively and reasonably allocate production resources.

Key node construction simulation 04 – Bim and integrated decoration – 1 The construction of decoration part product library and the integration of civil engineering and decoration, as an industrialized production mode, can promote the improvement of production efficiency in the whole process.

The application of visual design BIM is conducive to realize man-machine friendly cooperation and more refined design through visual design.

BIM design and simulation installation of unified parts such as integrated bathroom can realize design optimization, cost statistics and installation guidance..