Precast technology strongly assists the construction of emergency hospitals in many places. Analysis of five design points of precast

The construction period on site is short, the noise is small and the pollution is less, which can minimize the impact on normal medical work.

The cast concrete structure mainly used at this stage is the cast integral concrete structure, and its main precast component connection joints adopt the connection mode close to the performance of the cast-in-situ structure.

Steel can be recycled and has high material recovery rate, which meets the requirements of sustainable development.

Steel members have a high degree of industrialization, small transportation distance constraints and little environmental impact on the construction site.

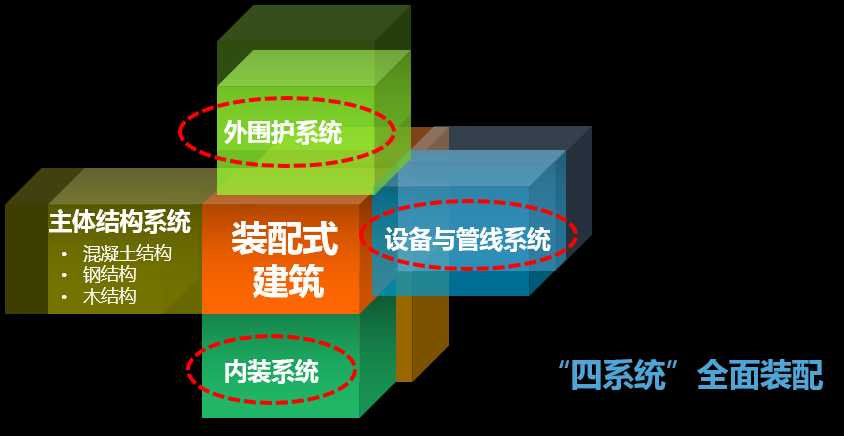

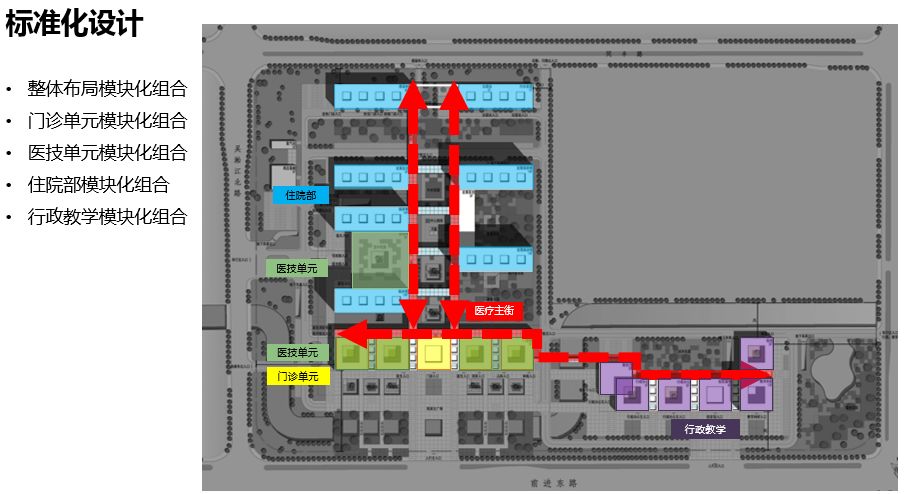

Precast buildings emphasize standardized design, factory production, assembly construction, integrated decoration, information management and intelligent application.

they are mainly buildings with three floors and below.

The main structural systems of precast concrete buildings include shear wall structure, frame structure, frame shear wall structure, frame core tube structure and so on.

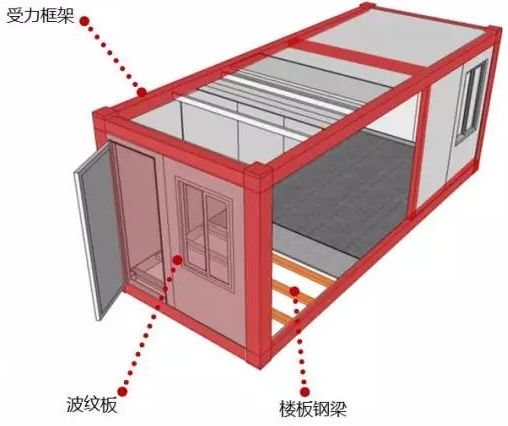

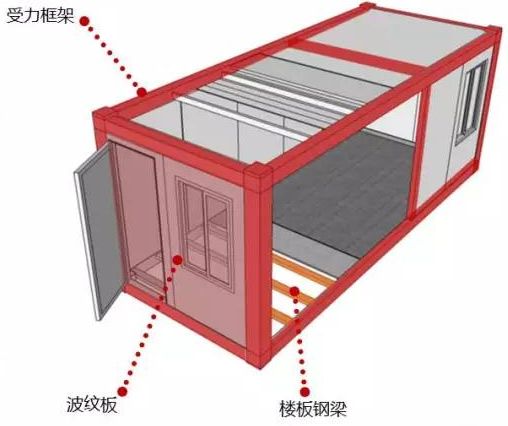

Fabricated steel structures can be divided into the following structural systems: steel frame structure, steel frame support structure (including steel frame central support, steel frame eccentric support and steel frame buckling restraint support structure), steel frame ductile wallboard structure, tube structure, mega structure, staggered truss structure, portal rigid frame structure, low-rise cold-formed thin-walled steel structure, integrated module building, etc_ Wood structure buildings are mainly used in traditional folk houses, residential buildings, comprehensive buildings, tourism and leisure buildings, cultural and sports buildings, temple buildings, etc.

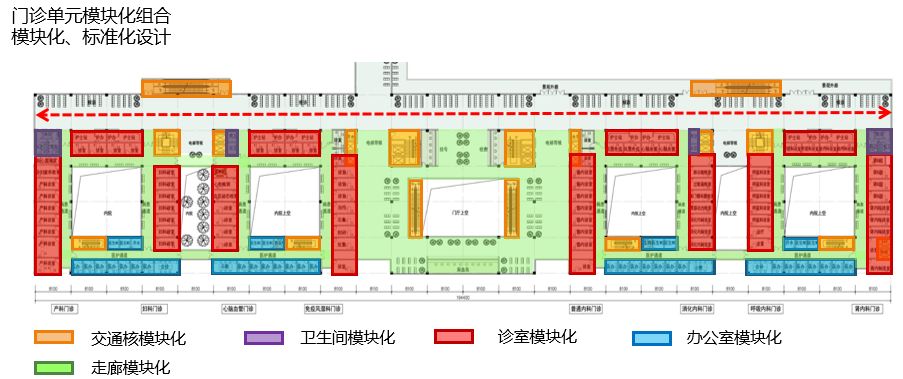

Standardized design, modularization, generalization, large space design, less specifications and more combinations; 2.

Therefore, it has become the key development object of China’s construction industrialization and industrialization.

High steel strength and small vertical member section can improve the space utilization rate.

Source: Zhuyi information_ After the outbreak of COVID-19, the assembly hospital building has become a hot topic in the industry.

At this time, the structural analysis can be carried out with reference to the mechanical model of the cast-in-situ concrete structure.

Catalogue_ I.

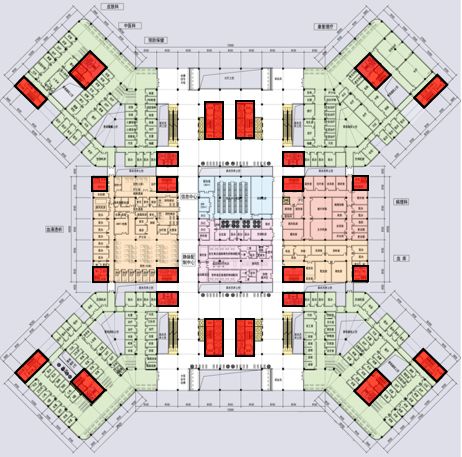

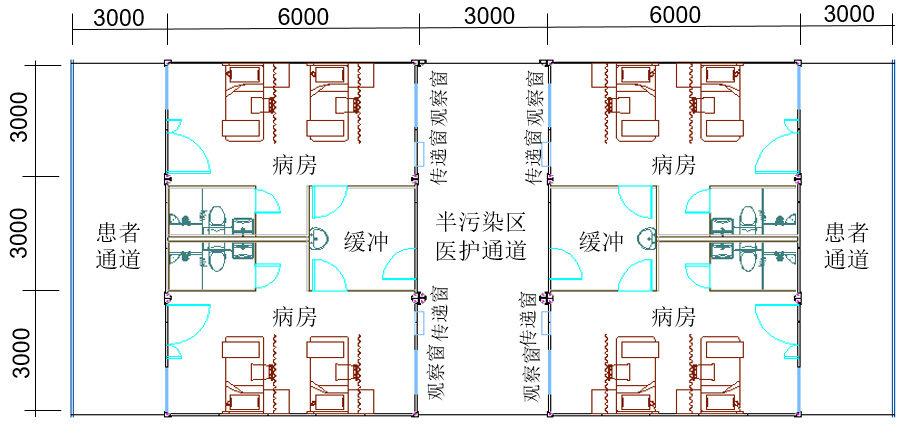

Precast hospital buildings generally adopt large space layout, modular combination and standardized design, which is easy to change the medical function.

Therefore, it has become the key development object of building industrialization and industrialization in China.

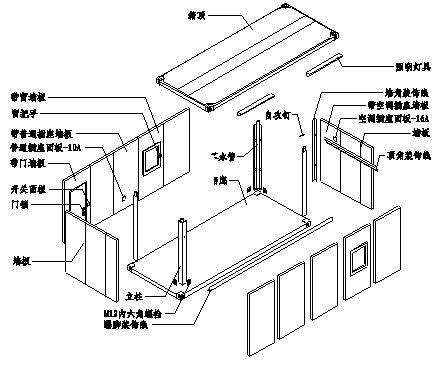

On site assembly, on-site assembly, dry construction, short construction period, little interference and little pollution; 4.

Compared with traditional cast-in-situ hospital buildings, precast hospital buildings have the following characteristics: 1.

Project management and EPC integrated management to reasonably control quality, safety, progress and cost; 6.

According to the structural form, domestic cast wood structures can be divided into: tenon and tenon structure, well dry wood structure, light wood structure, glued wood structure, square wood log structure, wood mixed structure, wood combined structure, etc.

The steel has good ductility, strong energy consumption capacity and good seismic performance.

characteristics of precast buildings II.

The main structure is separated from the equipment pipeline, which is convenient for rapid maintenance and replacement; 5.

However, its application in earthquake areas, especially in high-rise buildings in high intensity earthquake areas, needs to be further studied.

The factory production is universal and large-scale, with good quality and standardized interface of parts and components; 3.

Hospital buildings need a large space layout form to adapt to the reconstruction and expansion under normal operation, real-time update of medical processes, maintenance and replacement of equipment pipelines.

The steel structure has large span and strong modifiability, and can provide variable large space.

The precast building adopts the form of separation of equipment pipelines from the main structure, centralized arrangement of pipe wells and dry construction method, which is convenient for overhaul and maintenance.

Precast buildings can meet the requirements of hospital buildings, produce components in the factory and carry out dry construction on site.

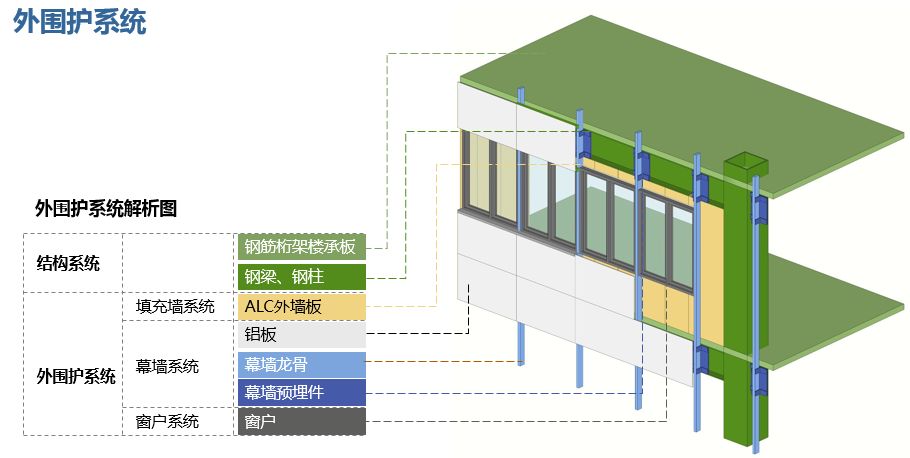

The supporting wall can adopt new energy-saving and environmental protection materials.

To this end, zhuyitai information specially invited Du Zhijie, vice president of the precast Architecture Institute of China architectural standards design and Research Institute and director of the medical architecture design and R & D center, and Zhang Jianbin, chief architect, to give you a comprehensive introduction to the precast architecture, focusing on the five design points of the precast hospital architecture.

Through the integration of four systems, the functional integrity and excellent performance of the building can be realized.

design points of precast hospital buildings v.

Among the above three structural forms, the cast steel structure is more suitable for hospital buildings.

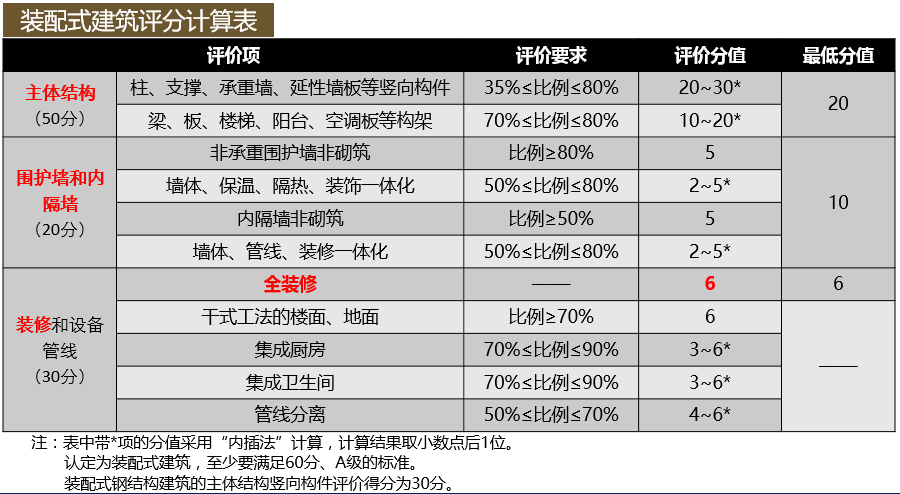

III_____ The evaluation of precast buildings has detailed provisions on the evaluation of precast buildings according to the evaluation standard for precast buildings (GB / t51129-2017) implemented by the Ministry of housing and urban rural development in February 2018: after the identification standard of precast buildings is determined, the assembly degree of precast buildings needs to be evaluated.

Intelligent application applies Internet and Internet of things technology to improve management and service quality.

At the same time, the factory mass production can reduce the cost.

evaluation of precast buildings IV.

To cope with the outbreak of major infectious diseases, the assembly mode can meet the needs of the rapid construction of a temporary emergency infection hospital, and many emergency hospitals adopt the cast building technology.

II_____ The structural types of precast buildings are classified according to the structural system, mainly including precast reinforced concrete buildings, precast steel structure buildings, precast wood structure buildings, etc.

Structural types of precast buildings III.

Steel structure has the advantages of light weight, high strength, good seismic resistance, flexible layout, small component section size, easy assembly, short construction period and high use area, and is conducive to industrial production and standardized production.

The precast concrete structure with non equivalent cast-in-situ connection joints such as dry connection is adopted for load-bearing precast members, which is simple and convenient to install.

Steel structure buildings are widely used in industrial buildings, public buildings, commercial buildings, residential buildings and other fields.

summary I_____ Features of precast buildings precast buildings refer to buildings in which the main parts of structural system, peripheral protection system, equipment and pipeline system and interior decoration system are integrated with factory produced parts and components.

With reference to the evaluation standard for green buildings, the grades of precast buildings are evaluated as grade A, AA and AAA..