[dry goods] during the landing of precast buildings, what should be controlled at each stage?

Precast steel structure, which takes steel columns and steel beams as the main load-bearing components.

Until 2010, domestic precast buildings are still in the stage of slow development and technical research.

In February 2018, the Ministry of housing and urban rural development proposed in the evaluation standard for precast buildings that the evaluation project can only be evaluated when the application proportion of precast components in the vertical components of the main structure is not less than 35%.

Yuehai land engineering management line person in charge 1 China’s Precast development overview and trend precast building refers to the construction process of building through technical means integration and system integration of various production factors in each stage of residential industrialization production by using modern industrial means and modern industrial organization.

However, the first mock exam has been difficult to continue, with the gradual disappearance of demographic dividend, the rapid rise of labor costs and the continuous loss of construction workers.

At the end of 2015, the state issued the evaluation standard for industrialized buildings.

Therefore, the weakening of demographic dividend will accelerate the upgrading of traditional construction industry to construction industrialization and make up for it through the improvement of labor quality.

Wu Xuwen engineering director of Guangdong Yuehai Land Group Co., Ltd.

The research of precast buildings also benefited from the benchmarking construction at this stage, realizing the transformation from “0” to “1”.

In addition, precast buildings are gradually showing the following trends in development.

In the past few decades, the cast-in-situ concrete construction model has benefited from China’s rich and cheap labor resources and has been widely developed.

In recent years, with the rapid development of China’s construction industry and the vigorous promotion and guidance of national policies, local governments have responded and actively implemented the development of precast buildings.

On September 27, 2016, the State Council issued the guiding opinions of the general office of the State Council on vigorously developing precast buildings, which defined the key areas for vigorously developing precast buildings and steel structures, the proportion of precast buildings in the future, new building objectives and key development cities.

In February 2016, the State Council issued several opinions on Further Strengthening the management of urban planning and construction, marking that the country officially promoted the promotion of precast buildings to the height of the national development strategy.

With the decline of the growth rate of the employed population in the construction industry, the imbalance between supply and demand promotes the increase of labor costs year by year, which will greatly reduce the cost disadvantage of precast buildings, and the long-term shortage of construction workers will also promote the change of construction production mode.

According to the “14th five year plan” (2021-2025), the urbanization rate of China’s permanent residents will reach 65% by 2025, but this goal is only close to the average level reached by middle and high-income countries five years ago.

A brief analysis of the development process of China’s assembly type in the 1950s, China embarked on the road of learning from the Soviet Union’s construction of socialism, carried out all-round and multi field learning on its experience in economic construction, comprehensively studied the industrialization and standardization of the Soviet Union, and vigorously introduced Soviet Union experts and technology.

It is clearly stipulated that precast buildings will account for more than 20% of new buildings in 2020 and more than 50% of new buildings in 2025.

A brief analysis of the development trend of precast buildings in China under the policy requirements and guidance, the prefabrication rate of precast buildings will be significantly improved in the future, and the market will achieve breakthrough growth.

Precast buildings have gradually entered the stage of large-scale development, showing a thriving development trend.

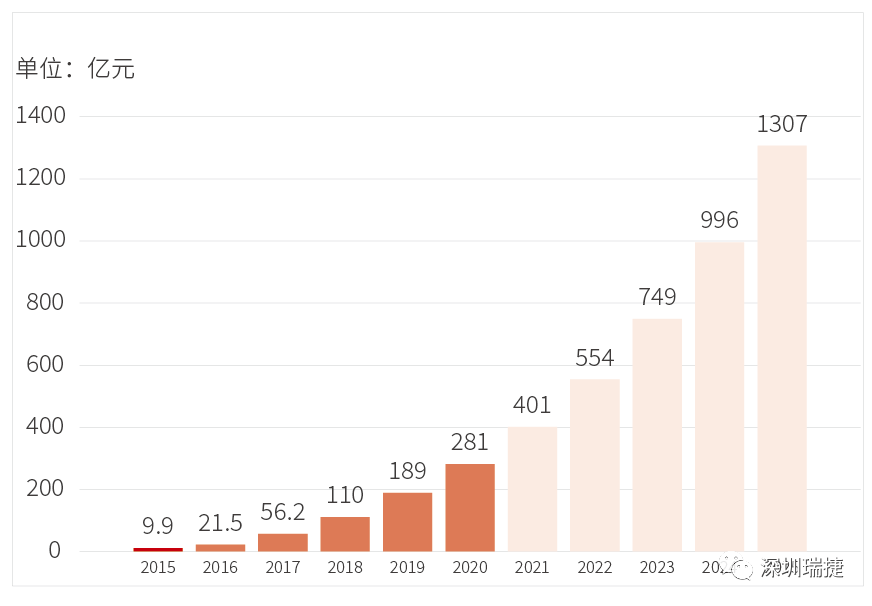

According to the statistics of the Ministry of housing and urban rural development and the National Bureau of statistics on the scale of the precast market from 2015 to 2020, relevant research institutions predict that the market scale of PC components will exceed 100 billion yuan in 2025.

It can be predicted that China’s urbanization rate will continue to rise in the future.

The opinion emphasizes that China must vigorously promote precast buildings and build a national precast production base; We will accelerate policy support and strive to make precast buildings account for 30% of new buildings in about 10 years.

The construction industrialization with high mechanization and low labor cost will have obvious advantages over the labor-intensive cast-in-situ construction mode.

What kind of development and changes has precast architecture experienced in China? What is its current situation and development trend? What are the problems in the landing of precast buildings at this stage? What are the key control points at each stage? This paper will make a brief analysis of the above problems.

△ statistical data on the market scale of PC component products in China from 2015 to 2025 source: the Ministry of housing and urban rural development and the National Bureau of statistics.

In May 1956, the decision on strengthening and developing the construction industry issued by the State Council proposed that “key projects, namely the construction of important industrial plants, mines, power stations, large bridges, tunnels, hydraulic buildings and other projects, must actively improve the degree of industrialized construction and actively adopt factory precast structures and accessories…” however, due to the planned economy, The low degree of marketization and technical level of the industry have led to the stagnation of the level of construction industrialization and the development of precast buildings.

This paper mainly includes the following two forms of precast buildings: precast concrete structure, which is a structure with precast concrete components (PC components) as the main components, precast in the factory, assembled and connected on site, and combined with some cast-in-situ concrete.

👆 Click the blue word, pay attention to it, and receive the dry goods of the industry at 8:00 every Monday.

For example, there are less than 10 workers on the production line of the professional factory with an annual production capacity of 1.2 million square meters, while the traditional manual operation needs more than 200 workers to produce the same number of floors; A 30 story building, using the precast construction mode, only needs 12 workers to work for 180 days, which improves the work efficiency by at least 30% compared with the traditional construction..