Overview of cast steel structure construction industry

Therefore, the steel structure cast construction business is mainly concentrated in several steel structure leading enterprises.

Precast steel structure buildings are more supported by policies than precast concrete structure buildings, and are expected to have better development prospects…

It is expected to achieve faster growth with the improvement of precast construction industry chain and the decline of construction costs in the future.

among them, technical barriers include a full set of technologies related to the whole construction project, including project planning, design, procurement, manufacturing and production, construction and installation, operation and maintenance and other construction project links, with extremely high technical barriers.

In the process of promoting the construction of new cities, the central government clearly proposed the development of intelligent construction, the promotion of green building materials, precast buildings and steel structure houses, and the construction of low-carbon cities.

The driving forces of industry growth are mainly reflected in: (1) precast buildings are environmentally friendly and energy-saving, which is more in line with the background trend of carbon neutralization and is strongly supported by policies; (2) China’s demographic dividend is gradually disappearing, and the cost of traditional cast-in-situ construction is rising.

Policy environment precast buildings are energy-efficient and reduce carbon emissions by more than 40% in the whole life cycle.

According to the development of precast buildings in China in 2020 announced by the Ministry of housing and urban rural development, the newly started precast buildings in China totaled 630 million square meters in 2020, with a compound growth rate of 50% in recent four years, accounting for about 20.5% of the new construction area.

It is an important technical path to achieve “carbon peak” and “carbon neutralization” in the construction industry, which is continuously supported by the policy.

From the perspective of structural form, the newly started precast steel structure building is 190 million m2, an increase of 46% over 2019, accounting for 30.2% of the newly started precast buildings.

1.

With the continuous development of the industrial chain, the cost of precast construction is gradually reduced, and the advantage is more obvious.

There are three main structural forms of precast buildings, namely precast concrete structure (PC), precast steel structure (PS) and precast wood structure.

4.

2.

Market space China’s cast steel structure construction industry has witnessed rapid growth in recent years.

Compared with the traditional building mode, the assembly mode greatly reduces manual operation and on-site wet operation, and integrates a large number of digital technologies, which is more in line with the development direction of modernization, intelligence and greening of the construction industry.

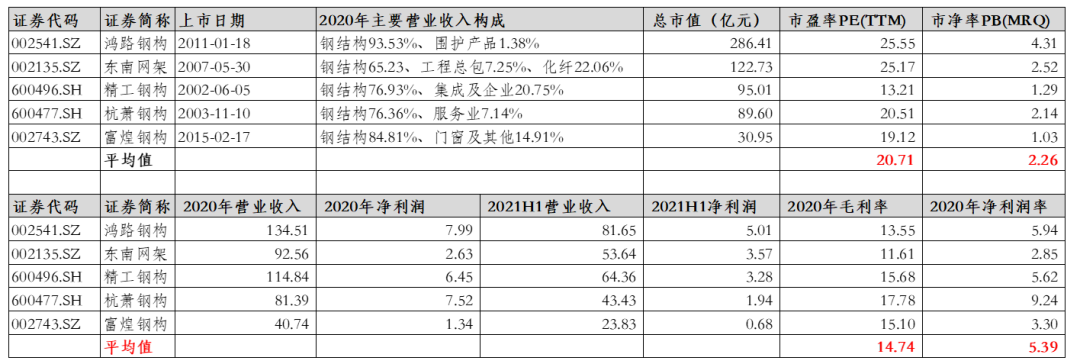

Performance of major listed companies in the industry 5.

About 2 / 3 of precast buildings in China are precast concrete structure, precast steel structure accounts for about 30%, and wood structure accounts for less.

Precast building refers to a construction method of precast components in the factory and connected and installed on site.

In March 2021, the central government issued the “14th five year plan” and the outline of long-term goals for 2035, emphasizing the promotion of low-carbon transformation in construction and other fields.

Double Head Lifting Pin Anchor

In terms of competition, in the field of steel structure construction, the state has made it clear at the policy level that the implementation subject of the development of precast buildings is precast construction enterprises, supported by design institutes and R & D institutions, and requires the implementation of EPC general contracting mode to promote steel structure precast buildings.

The 13th five year plan action plan for precast buildings issued in March 2017 and its supporting management measures clearly put forward that precast buildings will account for more than 15% of new buildings in 2020, including more than 20% in key areas, and precast buildings will account for 30% of new buildings in 2025.

3.

The cost of precast concrete structure is relatively low.

EPC general contracting mode puts forward higher requirements for steel structure green building enterprises, which not only need to have production and construction capacity, but also need technological innovation ability, planning and design ability, information comprehensive management ability, etc.

A small number of other precast buildings adopt mixed structure.

Summary: precast buildings are obviously supported by policies.

Barriers and competitive industry barriers mainly include technical barriers, scale barriers, experience barriers, etc.