Which is better than the traditional decoration or the precast decoration?

In fact, the core of the cast decoration is the research and development of connecting structural parts, and the innovation of installation methods.

The development of precast buildings is conducive to saving resources and energy, reducing construction pollution, improving labor productivity and quality safety, accelerating the transformation of the production mode of the construction industry, comprehensively improving the construction quality, and achieving energy conservation, emission reduction and sustainable development.

Assembled type: the high sound insulation wall can reach 45db by 134mm, which greatly reduces the waste of space.

Secondly, compared with traditional decoration, precast decoration also has the characteristics of “fast, good, economical and changeable”, and its advantages are also very obvious.

In this issue, we will describe it to take you to further understand the characteristics and advantages of the precast decoration.

The cast decoration is the optimization of traditional decoration, not the negation of the whole.

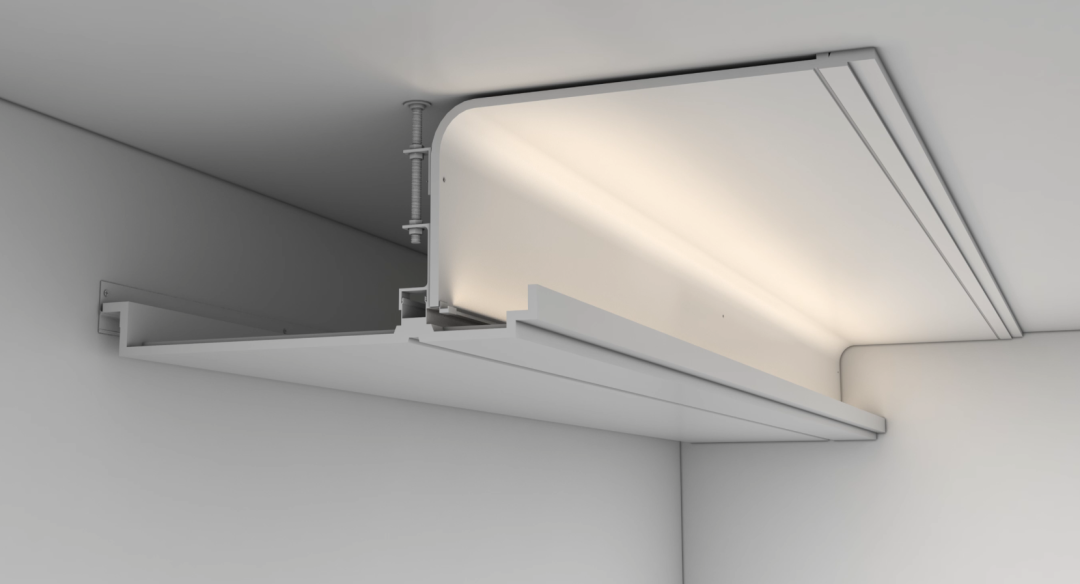

Assembled type: The honeycomb panel core layer is hexagonal aluminum honeycomb structure, and the closely spaced honeycomb is like many small I-beams, which can bear the pressure from the panel direction in a decentralized manner, so that the panel is evenly stressed, and the panel can still maintain a high flatness in a large area| Aluminum honeycomb composite board suspended ceiling high sound insulation wall system tradition: the air sound insulation capacity of 200 ㎜ thick traditional partition wall is ≥ 40db, meeting the requirements of relevant national standards.

Change – multi space variable, multi scene variable, local easy to refresh, hard outfit more personalized.

Self important and the flatness is not good enough.

02 What are the characteristics of Jinmantis assembly parts? The tradition of GRG ceiling module system: the modeling of traditional gypsum board ceiling depends on workers’ manual work.

This is an important embodiment of implementing the development concept of innovation, coordination, green, openness and sharing in the field of urban and rural housing construction, and promoting the innovation of construction methods according to the requirements of applicability, economy, safety, green and beauty.

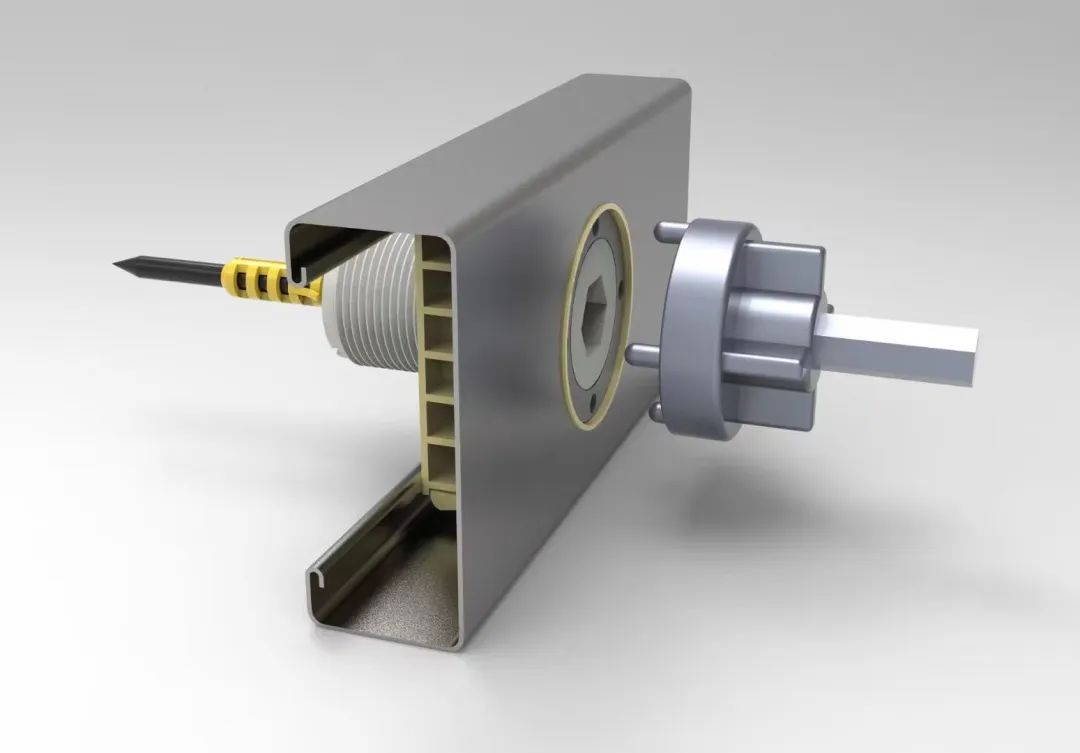

Compared with the traditional fixing method of screwing, rotating fixed chips can improve the work efficiency.

At the 20th National Congress of the Communist Party of China, it was proposed to “promote green development, accelerate green transformation of the development mode, and actively and steadily promote carbon peaking and carbon neutralization”.

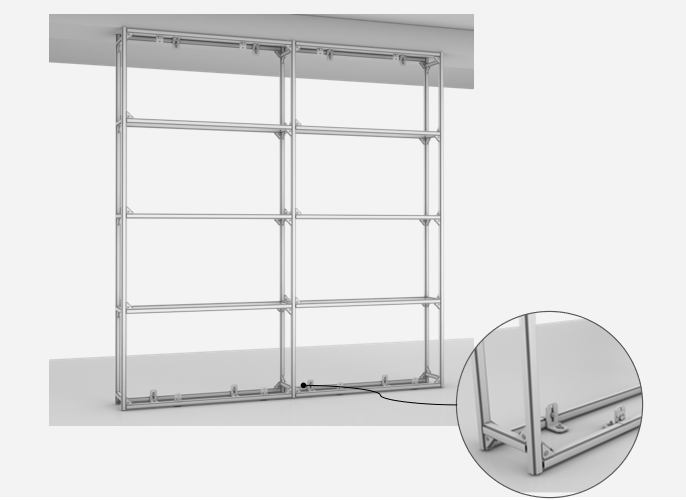

Save – more labor costs, more streamlined processes, more streamlined processes, and more convenient maintenance.

Assembly type: no welding, no drilling, cutting the corresponding length, using standard parts for connection; The structural scheme of light steel partition wall with any size can be realized; It is very convenient to assemble and disassemble, and the hot-dip galvanized material has good durability and can be reused; The large internal space can realize the integration of thermal insulation, heat insulation, sound insulation materials, mechanical and electrical, and structure; Making full use of hidden space can not only replace light steel keel as partition structure, but also be a solution for self-made furniture and other small load-bearing structures| The traditional honeycomb composite ceiling of the quick installation section steel connection system: the traditional ceiling has many processes, such as hanging bars, drilling, and splicing, which is complex in construction, greatly affected by the climate, and the material has deformation, subsidence, moisture, cracks, surface peeling and other quality conditions.

Wet operation is required and on-site plastering is required.

The water and electricity pipelines need to be grooved on site, causing dust pollution.

We briefly demonstrated the characteristics and advantages of the product through three issues.

A few days ago, the six space products of Golden Mantis Fabricated 2022 were newly released.

The traditional partition wall nailing is easy to crack and block, the labor intensity of slotting is high, and there is more dust, reducing construction waste.

In the future, Jintanglang Building Assembly Technology will, as always, closely follow the national building development policy, actively invest in research and development, adhere to the characteristics of practicality, safety, economics and green energy conservation as the research and development standards, and strive to make a breakthrough in the research and development of assembly products, so as to help the rapid development of assembly buildings across the country…

There may be quality problems such as wrong setting out, uneven base skeleton, poor connection of different radian intersections, or defects in the material itself, which affect the smoothness of the radian of the modeling, product deformation, sagging, top surface cracking, etc.

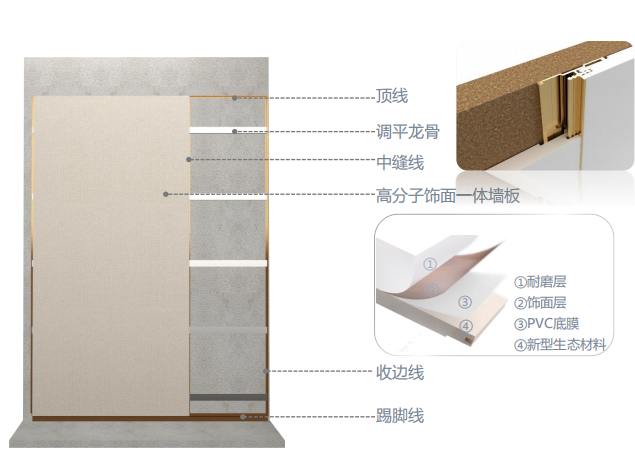

On the basis of the existing light steel keel wall, change the keel structure, improve the sound insulation performance of the keel, form a new type of high sound insulation wall with double cavity sound insulation structure of the wall, add multi-functional high sound insulation boards, and preset pipelines| High sound insulation partition effect assembly wallboard/leveling system Tradition: the first generation leveling keel fixing chip requires on-site manual positioning and screwing on the keel before wallboard installation.

Assembled type: the traditional and complex process is abandoned for the closing, and the ceiling can be seamlessly spliced with a slight push without a single wooden square to achieve a beautiful and unified effect| GRG suspended ceiling module system, quick installation steel connection system Tradition: traditional brick partition is not environmentally friendly, wastes land resources, pollutes the environment, and cannot be reused.

Low reuse rate and low labor efficiency.

Fast – fast construction, fast on-site cycle, fast worker training, and fast project occupancy.

It is difficult to construct in winter, which is easy to be hollowed and cracked, and the construction period is long.

In terms of reuse, it can improve the nondestructive utilization rate and can be quickly disassembled, reducing the labor cost| Polymer facing integrated wallboard | Nautilus wall leveling piece The above part is the introduction of some cast parts of Golden Mantis.

Assembled type: Fast wallboard installation is realized by improved leveling pieces and rotating fixed chips.

Good – the components are more homogeneous, the decoration precision is high, the construction environment is good, and the environmental protection is more healthy.

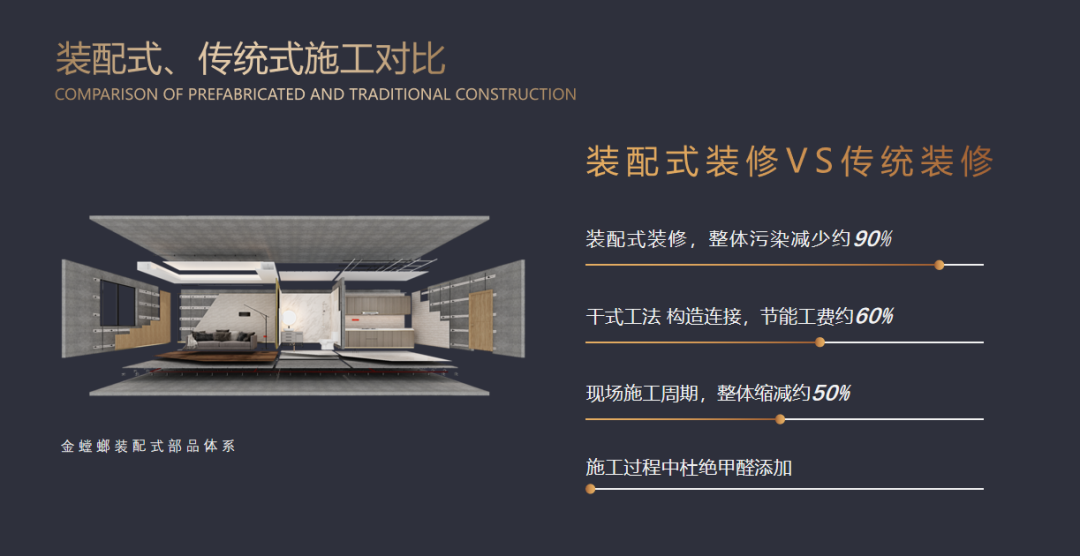

01 What are the advantages of precast decoration? Assembled decoration reduces overall pollution by about 90%; Dry construction method is used for connection, saving about 60% of labor cost; On site construction period is reduced by about 50%; Formaldehyde shall not be added during construction.