Typical engineering cases of precast buildings ① Longhai Yuegang Central Primary School Project

If the traditional cast-in-situ method is used for construction, it is difficult to erect the formwork support and ensure the quality due to the abnormal shape and large storey height; If mold prefabrication is adopted, due to small quantities and insufficient standardization, not only the mold opening cost is high, but also the production process is complex and difficult to achieve.

In order to solve the above problems and ensure the seismic performance of the building structure at the same time, the project conducts seismic reduction design for the teaching building and office building with high storey height and heavy load, and selects buckling restrained brace (BRB) as the energy dissipation and vibration reduction component, which can improve the seismic performance of reinforced concrete frame structure, especially the collapse resistance of the structure under rare earthquakes.

01 Fully assembled concrete frame system Fabricated concrete frame structure is one of the main forms of precast buildings, which is a new green construction method.

The seismic grade intensity is 8 degrees after adjustment according to the building type and site, and the building seismic requirements are high.

Figure 1 Realistic view of project completion 02 Main technical indicators of precast buildings This project is a precast building observation project in Fujian Province in 2018.

Application of 03PS-PC mixed pitched roof system The roof of the building scheme of this project has the traditional residential style with Minnan characteristics: glazed tile pitched roof+horsehead wall shape.

03 Participated units Construction unit: Douxiang Primary School in Haicheng Town, Longhai City Construction unit: Longhai Dongyue Urban Construction Co., Ltd.

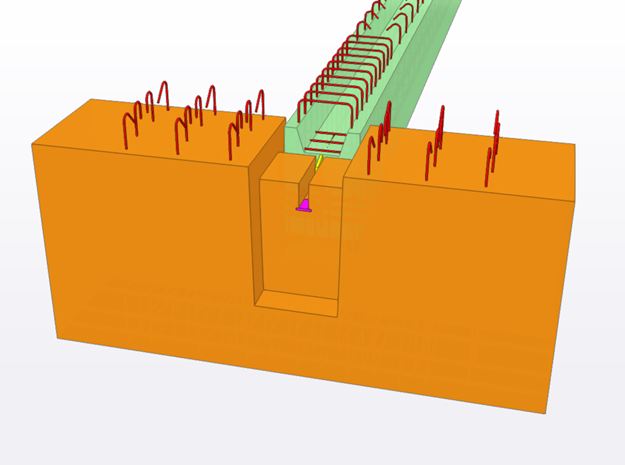

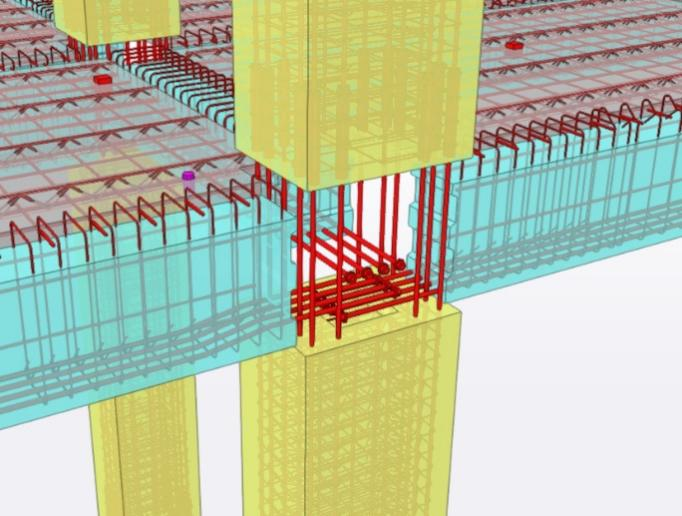

The joint of precast concrete frame structure is the key link of engineering quality control.

In order to summarize the experience and practice of precast buildings in our province, guide local governments to better promote the development of precast buildings, and advocate the advantages of precast buildings in terms of cost control, time saving, safety and reliability, the provincial department determined five cases as the first batch of typical engineering cases of precast buildings after the application of enterprises, the recommendation of the competent housing construction departments of cities with districts, and the review of experts, for everyone to learn from in combination with practice.

If the conventional reinforced concrete frame structure scheme with “resistance” as the main factor is adopted, there are problems such as too large beam column size and dense reinforcement for construction.

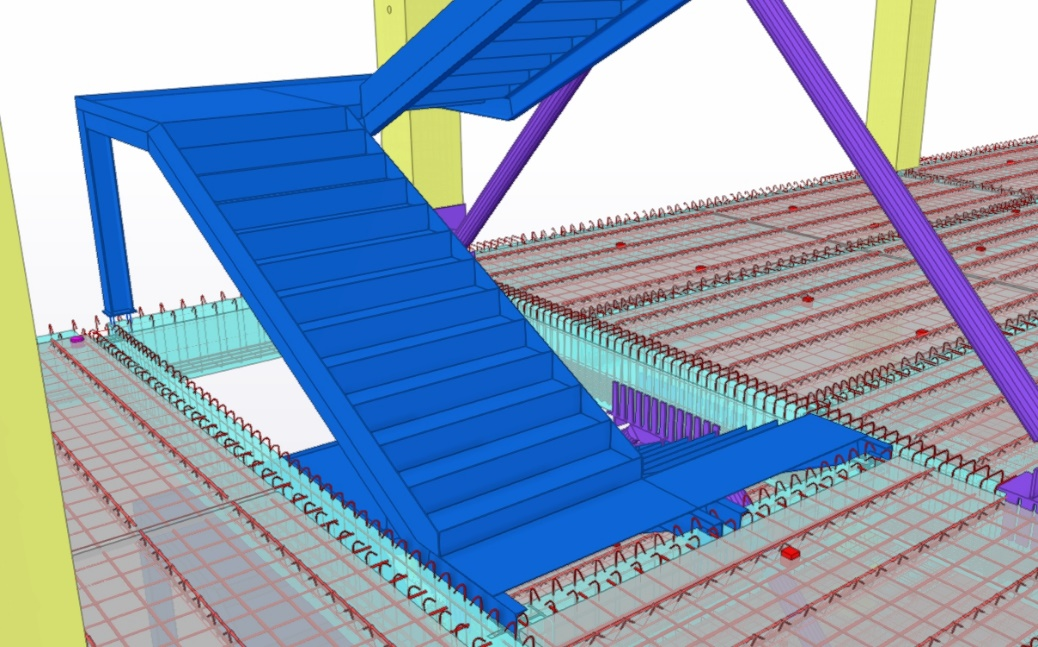

The precast components used include: precast columns, precast beams, laminated plates, steel stairs, PS-PC mixed pitched roofs, precast interior partitions, etc.

This project integrates a number of innovative technologies, such as fully assembled concrete frame system, energy dissipation and shock absorption precast structure, PS-PC hybrid structure roof, and full process and professional BIM application.

The project has successfully applied the technologies of new precast frame beam column joints, steel tongue and groove connection of primary and secondary beam joints, closely jointed composite floor slabs with innovative construction methods and cast steel stairs.

Design unit: Fujian Architectural Design and Research Institute Co., Ltd.

On the premise of ensuring economy and safety, the precast building technology will be perfectly combined with the traditional architectural style of Minnan.

The main technical route of precast structure design is to combine precast components with post cast concrete based on reliable connection technology of load-bearing steel bars, and connect the precast structure into a whole through reasonable structural measures of connecting nodes, so as to ensure that its structural performance has the same ductility, bearing capacity and durability as that of the cast-in-place concrete structure, and achieve the same effect as that of the cast-in-place concrete structure.

General contractor: Fujian Construction Engineering Group Co., Ltd.

According to the Measures for the Evaluation and Management of Assembled Buildings in Fujian Province (Trial), the assembly rate is 76%, which can be evaluated as a two star precast building.

II.

Longhai Yuegang Central Primary School I, Basic Information 01 Project Overview Longhai Yuegang Central Primary School is located in Haicheng Town, Longhai City.

Assembled construction technology and characteristics applied in the project.

04 The whole professional BIM integrated collaborative design deeply integrates BIM technology with collaborative design, and establishes LOD400 models of buildings, structures, equipment, cast interior partitions, precast concrete components, and steel structure components, realizing data sharing, intercommunication, and collaboration among disciplines, greatly shortening the time for in-depth design, and reducing errors, omissions, and defects in in-depth design..

The technical indicators of precast buildings are as follows: 1.

In order to better adapt to the requirements of building functions and improve the quality and construction speed of the project, the project gives full play to the advantages of EPC.

The project was completed in October 2019, and passed the review of precast building construction stage in 2020.

In order to solve the above problems, PS-PC mixed pitched roof system has been successfully applied in this project.

According to the Measures for the Certification and Management of Industrialized Buildings in Fujian Province (for Trial Implementation), the monomer prefabrication rate is 61.5%; 2.

According to the national standard Evaluation Standard for Fabricated Buildings (GB/T51129-2017), the monomer assembly rate is 70%, and the vertical components are 100% precast, which can be evaluated as Class A precast buildings; 3.

Deepening design unit: Fujian Construction Engineering Fabricated Building Research Institute Co., Ltd.

It covers an area of about 36 mu, with a building area of about 21000 m2.

Construction unit: Fujian Construction Engineering Group Co., Ltd The Company and the Supervisor of Fujian Seventh Construction Group Co., Ltd.: Fujian Guangzheng Engineering Project Management Co., Ltd.

It is composed of three 5-storey teaching buildings, one 6-storey office building, one 4-storey complex building, a rain proof playground, a corridor and other single buildings.

See Figure 1 for the completion of the project.

The design team has worked closely with the construction team to prepare two provincial construction methods, namely, “precast building precast slab (one-way slab) construction method” and “precast building precast column sleeve grouting connection construction method”, and has obtained good social and economic benefits.

Preface In recent years, our province has continued to steadily promote precast buildings and achieved positive results.

The enterprise actively explores and creates a batch of high-quality precast construction projects.

For the cast integral frame structure, it will also cause problems such as difficulty in the reinforcement arrangement of beam column joints, excessive component weight and increased construction difficulty.

02 Energy dissipation and shock absorption precast structure This project is located in a seismic fortification area of 7 degrees (0.15g).

The seismic fortification intensity is 7 degrees (0.15 g), and it is a key fortification building.

Parts manufacturer: Fujian Jianchao Construction Group Co., Ltd.