Fabricated architectural design: how to maximize benefits?

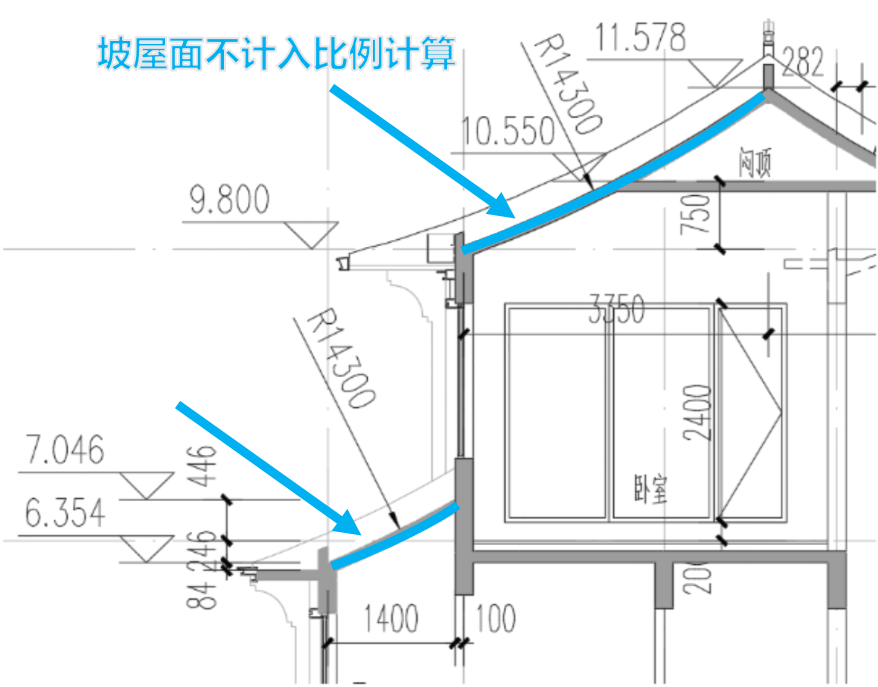

At the special review meeting of assembly scheme and the special technical report meeting on the terms of Shaoxing Assembly Building Evaluation and Interpretation, they fully communicated with experts, and finally passed the identification of several evaluation items, such as the identification of the integration of ALC interior wall pipelines, the identification of integrated kitchen and bathroom standards, and the identification of BIM technology, As well as the proportion calculation of precast horizontal components can not be included in the Chinese style pitched roof of townhouses, under the premise of not significantly increasing the cost, nearly 20 points of assembly rate were obtained, effectively controlling the cost increment of precast construction.

In combination with the layout of tower crane yard, the component yard was optimized to ensure the smooth lifting of components.

In April 2020, Zhongtian Architectural Design Institute officially launched the Shaoxing Yellow Wine Town Project with an investment of more than 30 billion yuan.

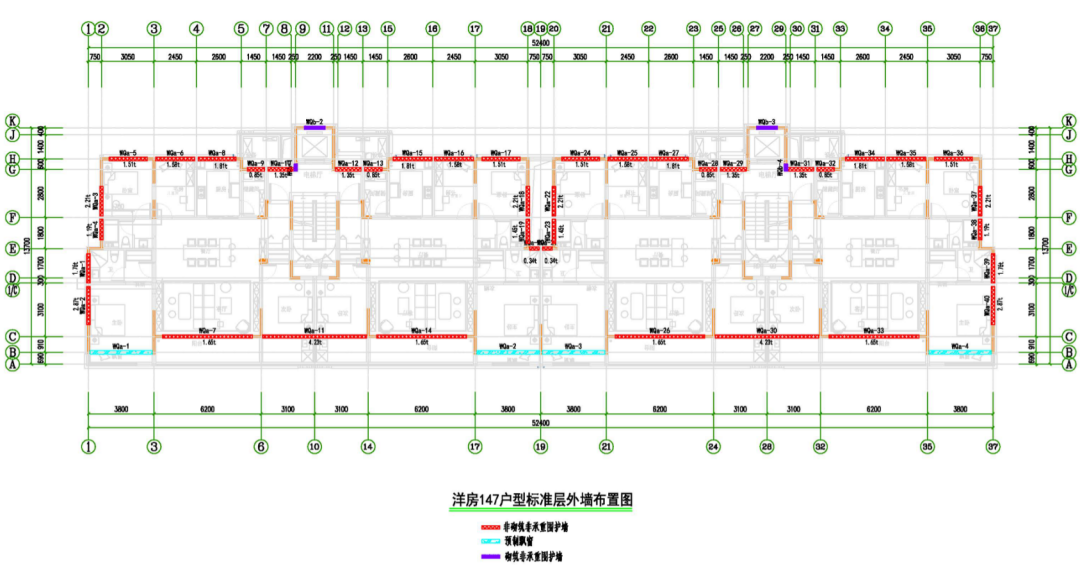

The original architectural scheme can split the reward area of the exterior wall to less than 800 square meters.

Shaoxing City is strict in the identification of assembly type evaluation items, and some common application technologies in other regions may fail to pass the identification.

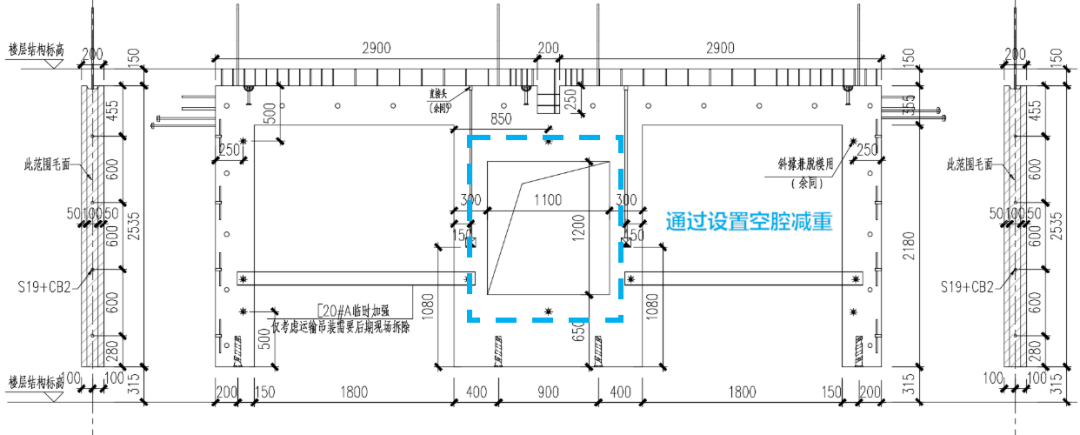

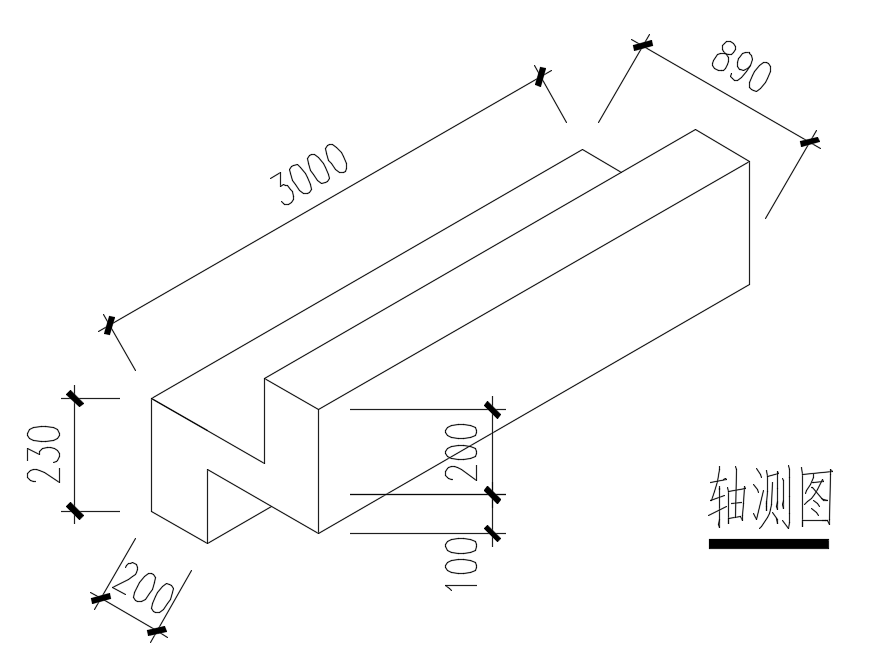

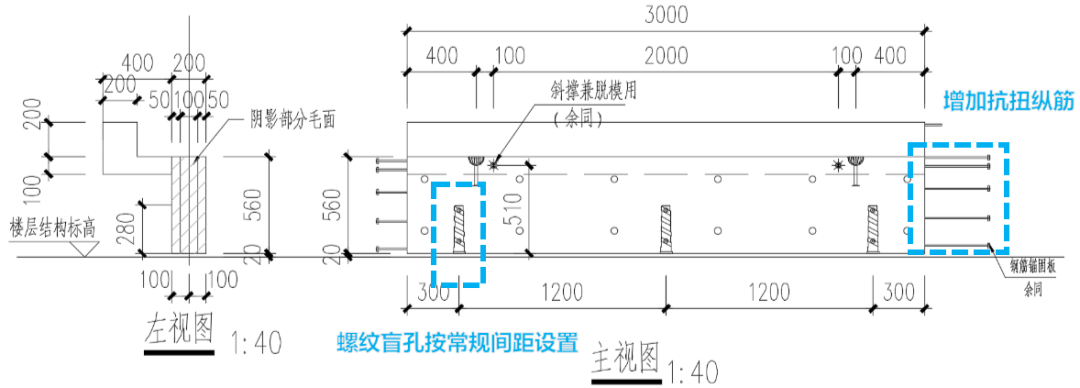

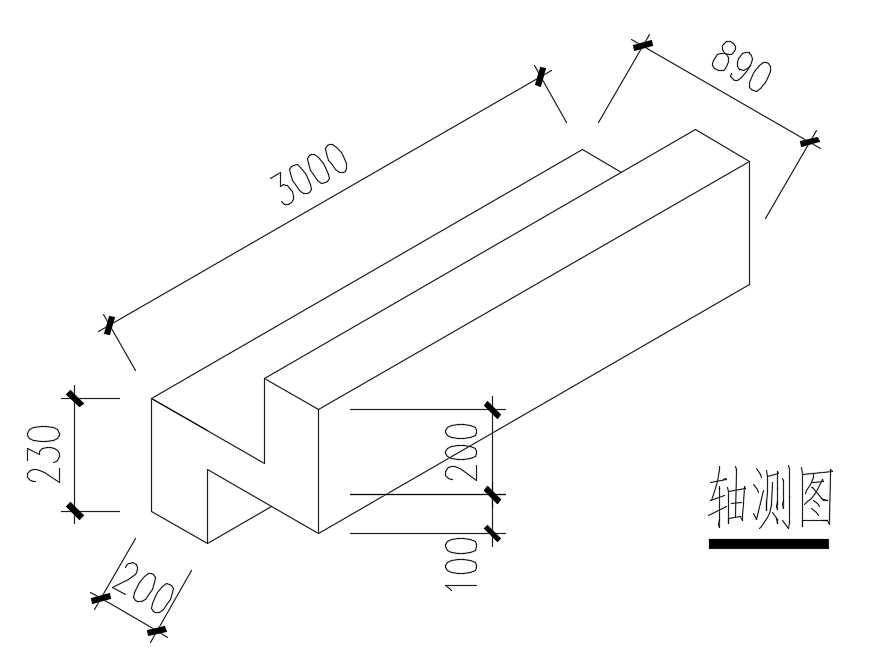

Therefore, the design team has added the cast-in-situ column on the beam in the middle of the bay window, divided the precast bay window into two sections, and transmitted the force by setting torsional reinforcement anchored into the wall columns on both sides, which not only reduces the weight of components and reduces the embedded reinforcement, but also ensures the safety of force transmission and improves the convenience of construction.

Trapezoid Rubber Magnetic Chamfer

Considering the huge impact of architectural scheme design on the project, the assembly design team of Zhongtian Architectural Design Institute intervened in advance and cooperated with the architectural scheme design team comprehensively and deeply in the project scheme design stage.

Compared with traditional manual drawing, the modification time can be reduced by at least 80%, effectively avoiding the impact on the construction progress.

Considering that the bay window is long, the way of stressing the bottom sleeve reinforcement requires more sleeve reinforcement to be embedded.

Through the optimization in the design stage, zero impact on the selection and location of tower cranes is achieved, which not only reduces the construction cost, but also ensures the construction efficiency.

▲ More boutique products, pay attention to how the precast architectural design of “Search for Architecture” can maximize the benefits for Party A.

Under the expectation that the sales unit price exceeds 20000 yuan, It will increase the sales of the project by more than 30 million yuan.

The development of the industry urgently needs to change the passive assembly design method which only aims at meeting the specifications.

The design team, based on the characteristics of the project, makes an overall arrangement of the components in each block.

In order to avoid the above problems, the design team adopted segmented, hollow and other technologies for some overweight exterior walls, reducing the maximum component from 4.5 tons to 2.8 tons.

In order to increase the sales, Party A hopes to get as much incentive area as possible.

With its profound technical accumulation and good market reputation, Zhongtian Architectural Design Institute achieved the precast design task of the project.

Taking Block 3E as an example, the planned land area of this block is 38831.8 square meters, and the building area is 47963 square meters, all of which are residential buildings, consisting of 10 western-style houses and 7 townhouses, all of which are cast.

Based on the actual situation of the project, from the perspective of Party A, under the premise of meeting the specifications, Zhongtian Architectural Design Institute has made in-depth exploration in terms of expanding the incentive area, reducing the construction cost, improving the construction quality, etc., so as to promote the advantages and circumvent the disadvantages of the cast construction, and achieve a win-win situation for Party A, design and construction.

▼ The column on the beam shall be reserved.

As a special design module for buildings, the precast design needs to be coordinated with the architectural design upward and the construction needs downward.

Whether the connection node structure of precast components and cast-in-place parts is reasonable or not directly affects the project quality and production and construction difficulty.

Using the relevant self-developed procedures and plug-ins, the detailed drawing of the components is disassembled into three parts: structural dimensions, fine decoration points, and detailed nodes to ensure the accuracy and standardization of the drawings.

The design scheme has a decisive impact on the project cost, and the construction cost of precast buildings is higher than that of traditional buildings.

If there are heavy components such as precast columns and precast wallboards, only the tower crane model can be added, which will have a great impact on the construction cost, while heavy components also increase the difficulty of installation, affecting the construction quality and efficiency.

Since 2013, Zhongtian Holding Group has taken the lead in carrying out the industrial layout in the field of precast buildings nationwide, and is committed to realizing the integrated precast construction and service mode of engineering project design, construction, operation and maintenance driven by the digital chain..

At the same time, the design team also retains the convenience of batch adjustment for possible subsequent building or fine decoration adjustment, realizing rapid modification without omission.

The reasonable stress of precast bay window and how to install it are the difficulties.

The project is composed of multiple blocks, covering residential, commercial, school and other forms of business.

The precast exterior wall components of this project are generally heavy.

The precast building is the main direction of the transformation and upgrading of the construction industry.

After on-site construction, the quality of drawings and the efficiency of later service have also been unanimously recognized by all parties.

The project conforms to the local policy requirements on the reward area, so the precast exterior wall technology is adopted.

The project has a large volume and a large number of house types.

In order to meet the needs of facade modeling, some house types of this project adopt the design of wide bay window in the guest restaurant.

Precast components of precast projects are usually hoisted by tower cranes.

Precast components need to be produced in advance, so the precision of detailed design is very high.

At the early stage, the assembly design team of Zhongtian Architectural Design Institute cooperated with Party A to conduct field research on key evaluation technologies.

Only with a comprehensive understanding of relevant policies and specifications, and an in-depth study of the process technology of each evaluation item, can the best evaluation item be selected according to local conditions to minimize the cost increment caused by assembly construction.

On the one hand, it increases the difficulty of on-site alignment installation, on the other hand, the grouting quality also affects the stress safety of components.

On the premise of not affecting the overall effect of the facade, through adjusting the position of the precast exterior wall, fine-tuning the size of the window opening, optimizing the length of the shear wall wall limb and other measures, the precast exterior wall standardization is achieved as far as possible, and finally 1368 square meters of reward regardless of the area is obtained, which is concentrated in the area of western-style houses that are easier to construct.