Open caisson type and cast underground parking garage are an eye opener!!!

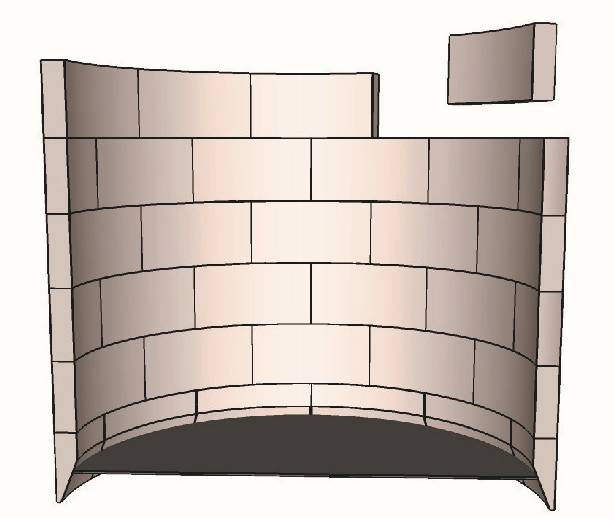

During assembly, not only the verticality and block stability of the shaft shall be ensured, but also the vertical joints of adjacent layers shall not be within the same vertical line.

Therefore, the purpose of research and development of precast caisson type underground mechanical parking garage is to solve the parking problem in some cities by building underground parking garages on small plots at surrounding corners such as old urban communities, parks and green spaces, and commercial areas.

5) The prefabrication of warehouse components in the factory can maximize the improvement of common quality problems such as concrete cracking and leakage, and improve the overall safety level, fire resistance and durability of the garage.

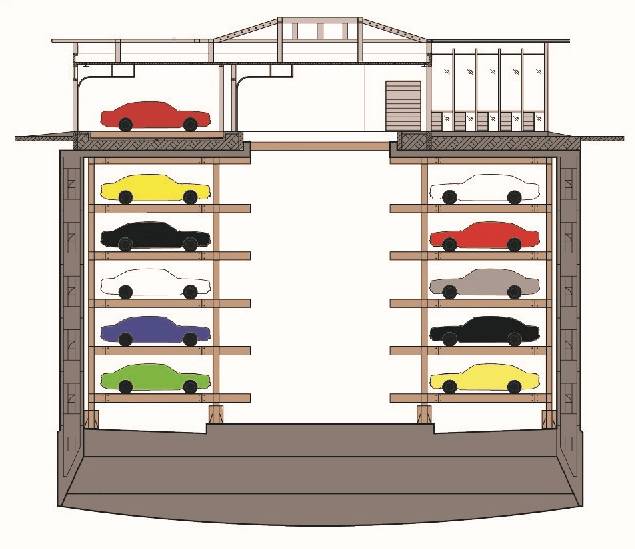

As a pilot project, each garage is designed with 10 parking spaces, 5 floors underground, and 50 parking spaces.

jointly contracted the rare precast assembly caisson type underground machinery parking garage nationwide has been completed.

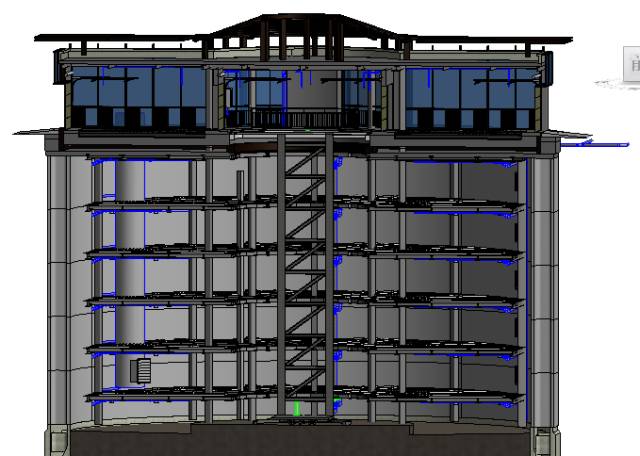

In the process, BIM technology is used to timely adjust and correct the component assembly and construction collision problems of various disciplines, simulate the use process of vehicles of various specifications, and check parking errors.

The open caisson type underground mechanical parking garage project around the administrative center of Haicang District consists of two independent warehouses, which are respectively built in the cultural and artistic center and administrative service center of Haicang District, Xiamen City.

It is a practical project to study and solve the parking problem in old residential and commercial districts.

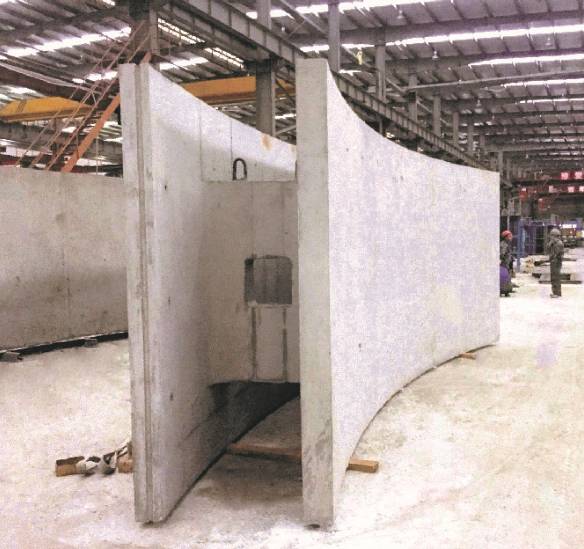

4) The cylinder is divided into double skin cavity structure for prefabrication, and steel plates are embedded at the edge of each component, which are welded continuously during assembly to form a closed joint.

Aerial View of the Cultural Center The completed entity of the cultural center (weakened in greening, beautiful and small land occupation) 2 Engineering method The method used in this project is to first divide the shaft into six layers along the height, the bottom layer is the cutting edge layer, and the other five layers are standard layers, each layer is divided into 10 pieces, and each inner and outer wall is mutually consolidated through connecting ribs.

The main construction period is 5 months and has been completed.

The underground area of a single garage is 380m2, and the ground area is 120m2.

Perspective view of garage structure The garage body is constructed with precast assembly technology combined with sinking technology of open caisson.

It is the first underground parking garage in Fujian Province to use precast assembly+open caisson construction method and reasonably use the corner green space underground space.

has applied for an invention patent, which can be productively produced with strong reproducibility.

4) Pour reinforced concrete into the cavity of the standard layer at one time, and continue to excavate until the shaft of this layer sinks in place; 5) Repeat steps 3) and 4) to install other layers of the shaft until the shaft sinks to the preset depth of 17.05m layer by layer; Aerial view of standard layer assembly, excavation, sinking and assembly of cutting edge layer 6) The bottom of open caisson is composed of plain concrete bottom sealing, reinforced concrete bottom plate and ballast concrete; 7) Main steel structure and equipment installation.

The standard cutting edge block will be transported to the site for assembly, and the inner cavity between the inner and outer walls will be poured with reinforced concrete to ensure the connectivity and safety of the cast shaft.

2) The sinking method of open caisson is used to integrate the foundation pit support and the double wall of the structural exterior wall, which belongs to the reverse construction method, reducing the working procedure and saving materials.

3) Cylindrical structure is adopted, with uniform stress, good integrity of reinforced concrete poured in the cavity, safe structure, no support, improved excavation efficiency, and convenient for construction personnel to work in the well.

The application of 3BIM technology in the installation of sinking and back sealing equipment The project is small in size, but has all the necessary features.

In particular, it plays a role in assembly design, steel structure and equipment structure matching design, material procurement, cost control, use function review, construction period control and other aspects.

The combination of the two construction methods and innovation [precast assembly+caisson sinking method] 1) caisson sinking is generally used in the bridge field, and usually adopts cast-in-situ construction.

7) It is conducive to environmental protection, land conservation and energy conservation..

1 Research and development background and overview In recent years, the number of motor vehicles has increased rapidly, which is in sharp contradiction with the lagging construction of urban parking facilities.

There are few supporting parking spaces in the old residential areas built in the city, the demand for parking is huge, and the surrounding buildings are dense, but it is impossible to excavate large parking garages, so the contradiction between supply and demand is more serious.

This cross field application of large-diameter caisson combined with precast assembly is the first successful practice project.

6) The progress of the project is fast, and the progress of the precast caisson garage is about 50% faster than that of the traditional way.

Authorized source: Xiamen Precast Building Development Promotion Platform ID: XMZPJZ is invested and constructed by Xiamen Haicang Urban Construction Group Co., Ltd., and Xiamen Overseas Investment Engineering Construction Co., Ltd., Xiamen Municipal Engineering Design Institute Co., Ltd., and China Railway Science and Construction Co., Ltd.

After the precast blocks are spliced into a ring overlay layer, “staggered pouring of inner cavity self compacting concrete” is the core of structural waterproof design.

First, the number of motor vehicles has increased, and the contradiction between supply and demand of parking spaces is prominent; Second, the planned parking spaces are seriously insufficient; Third, land resources are scarce and parking facilities are difficult to provide land; Fourth, the parking management system lacks overall planning.

The warehouse is small.

BIM Application 4 Innovative Advantages This project is invested and constructed by Haicang Urban Construction Group.

Before assembly, the setting out and tooling rack setting shall be prepared to ensure the accuracy of assembly; 2) Pour reinforced concrete into the inner cavity of the cutting edge layer at one time, and then excavate the ground around the cutting edge layer to make the cutting edge layer sink in place; 3) The hoisting standard block shall be spliced with the top of the installed shaft, and the adjacent standard blocks shall be spliced successively to form the upper layer of the shaft.

The following are the research and development background, overview, engineering methods BIM technology application and innovation advantages are introduced in detail.

The on-site construction steps are as follows: 1) Splice the cutting edge block into a cylindrical cutting edge layer.

China Railway Science and Construction Co., Ltd.

All internal and external walls are precast in the factory with high-precision large set shaped steel formwork, which is highly standardized and modular.

Therefore, making full use of underground space scientifically and reasonably is bound to become a trend and an effective way to solve the “parking problem”.

1.