This technology enables the detection of cement rods to “move”

In the past, the cost of each sampling inspection and the round-trip test site was usually over 10000 yuan, which far exceeded the cost of a single cement tower.

It is not an easy task to send the cement pole to the quality inspection workshop for testing.

Cement poles are cast together with steel bars and cement, making them a veritable “hard bone”.

After the rainstorm, the emergency repair personnel are replacing the broken cement pole.

Therefore, considering efficiency and efficiency comprehensively, in the field of power engineering construction, the quality inspection department usually selects 1-3 samples from each batch of cement poles for factory testing in accordance with the national standard “Circular Concrete Poles” (GB4623-2014) based on the principle of full coverage of suppliers and batches.

What are the benefits of “targeted random inspection”? The design concept of the “Mobile Tower Quality Inspection Intelligent Platform” is to lightweight and improve the originally bulky and non intelligent equipment, breaking the previous mode of “pole finding equipment” and transitioning to “equipment pole finding”

.

Strong cement poles also have “soft ribs”.

There are many items to be tested for the cement pole, mainly including the compressive strength of concrete, appearance quality, size deviation, mechanical properties and thickness of protective layer.

When it comes to cement poles, everyone should be familiar with them.

However, even hard bones have “soft ribs”.

Is there a better way to inspect neatly stacked cement poles and towers waiting for cranes to transport them to the quality inspection center? State Grid Jinhua Power Supply Company and State Grid Zhejiang Materials Company have changed the traditional sampling and inspection method and jointly developed the first “mobile tower quality inspection intelligent platform” in China, opening up the “targeted random inspection” mode for tower materials.

Due to the slender shape of the cement pole, it is necessary to rent large trucks and cranes for each inspection and transportation.

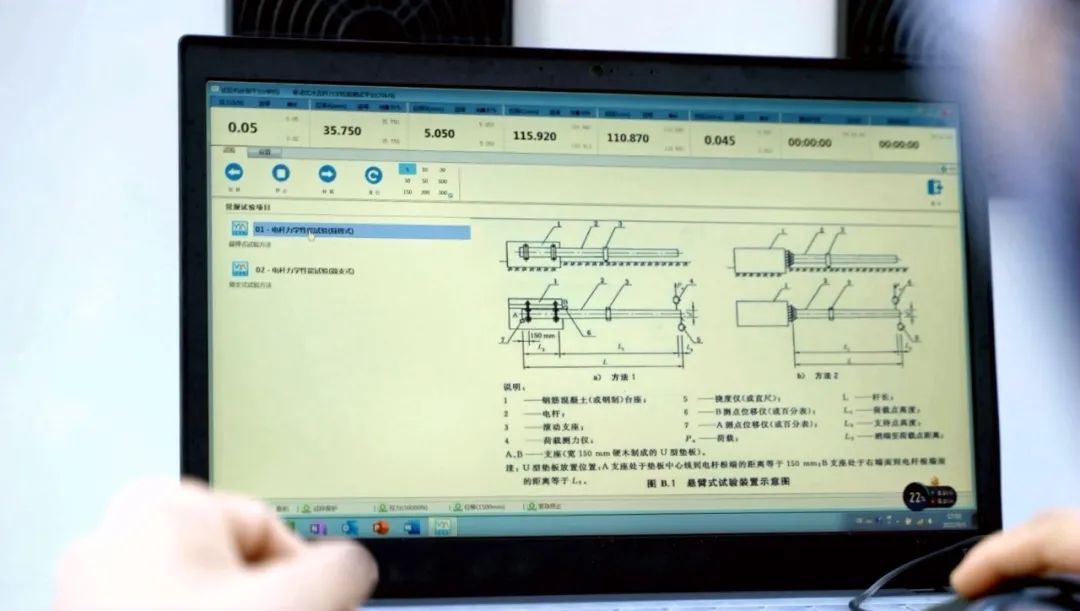

The testing of basic mechanical properties mainly relies on conventional equipment such as deflection testers, chain hoists, and load sensors to conduct “on-site fixed inspections” at qualified testing sites.

It is a load-bearing component for supporting conductors in transmission and distribution lines, commonly used for medium and high voltage overhead lines of 10 kV and above.

The cement pole structure contains a large number of long and thin components, with numerous connection nodes, and factors such as design, material selection, transportation, and storage environment can have varying degrees of impact on the quality of the pole body.

The production technology threshold for materials such as cement poles is relatively low, with numerous manufacturers, complex supply channels, and uneven quality, which requires product testing.

Lightweight and portable testing facilities greatly improve the efficiency of quality inspection work.

Cement poles and towers support long-distance transmission of electricity through wires, and are widely used in distribution grids.